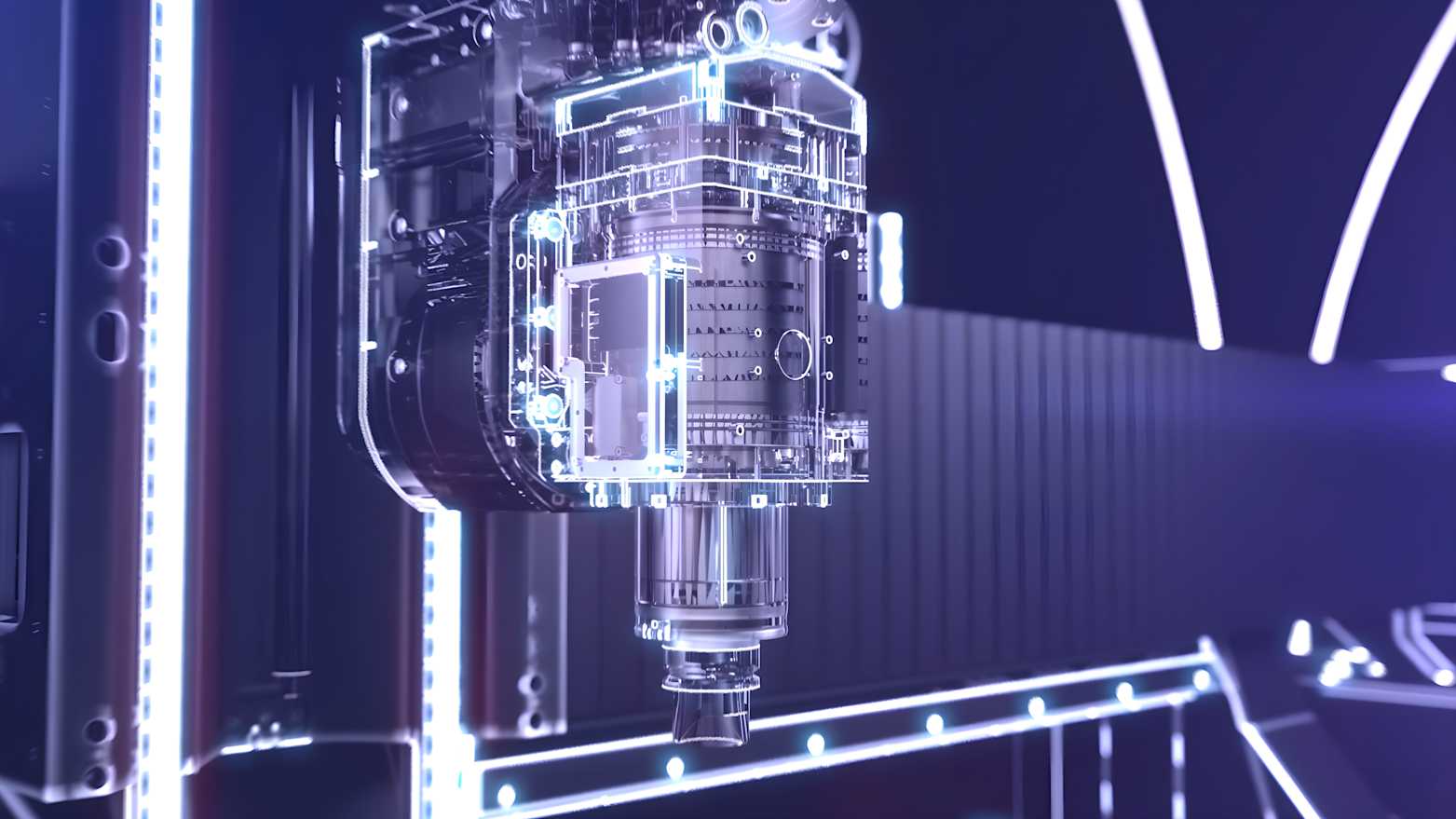

A New Era in CNC machining

The world of CNC machining is evolving, and at the forefront of this innovation is the Explora Multi Pro M S. Designed to set new benchmarks in precision and repeatability, this machine is redefining the machining of high-precision technical components for industries such as automotive, aerospace, and engineering plastics.

What inspired the development of the Explora Multi Pro M S?

“From the very beginning, our goal was clear: to set a new benchmark in precision and performance for CNC machining," explains Paolo Tarchioni, Biesse Chief Product Innovation & Development Officer. "The Explora Multi Pro M S is designed to meet the most demanding applications, ensuring exceptional accuracy and repeatability. By integrating Siemens' next-generation components, such as high-performance motors, drives, and the Sinumerik One numerical control system, we've developed a machine that delivers top-tier results in every production cycle.”

How does this new model fit into the broader Explora range?

"With the Explora Multi Pro M S, we are expanding our offering to provide even more specialized solutions for precision machining. This model complements our existing lineup by focusing on high-precision components, multi-material processing, and seamless automation. It is particularly well-suited for customers who require flexible, high-speed, and high-accuracy machining across various industries."

"The Explora Multi Pro M S is a true game-changer. It is designed for industries requiring high-precision technical components, such as automotive, aerospace, and engineering plastics. By combining flexibility, performance, and ease of use, it redefines machining efficiency." "One of its greatest strengths is its advanced 5-axis capability. Equipped with a high-precision 5-axis head, an automatic tool changer, and a large tool magazine, the Explora Multi Pro M S enables complex machining operations with absolute precision. Manufacturers working with intricate geometries and high-performance materials will find this solution indispensable."

Versatility in material processing

One of the key advantages of the Explora Multi Pro M S is its versatility. It can process a wide range of materials, including plastics, composite materials, and light alloys. Thanks to its robust structure and spacious worktable, operators can seamlessly transition between different projects, maximizing efficiency without compromising quality.

"Precision is at the core of this machine," says Tarchioni. "The Explora Multi Pro M S features an advanced dimensional and compensation control system that ensures every component meets the highest quality standards. A precision contact probe and a laser tool setup system work together to maintain consistent accuracy and minimize errors throughout the production process."

Durability is essential for long-term performance. That’s why we applied the Finite Element Method (FEM) to reinforce critical points of the machine, reducing vibrations and increasing structural rigidity. This ensures stable and reliable operation, even under the most demanding conditions.

A future-ready solution for manufacturers

"The Explora Multi Pro M S is more than just a CNC machine; it represents the future of high-precision manufacturing," concludes Tarchioni. "Whether you're working on high-volume production or complex, custom components, this machine will elevate your operations with unmatched accuracy, reliability, and efficiency."