Stone industry and workshop

Simeg is distinguished not only by the quality of its products and services, but also by its dedication to sustainability and innovation, which make it a reliable, cutting-edge partner in the stone materials processing industry.

Simeg is a company with deep roots in traditional stone processing but with a focus on the future and strong commitment to innovation and sustainability. The combination of craftsmanship and advanced technologies enables the company to offer high-quality, custom-made products to customers, both for interior design and contract projects, as well as luxury construction and boating applications.

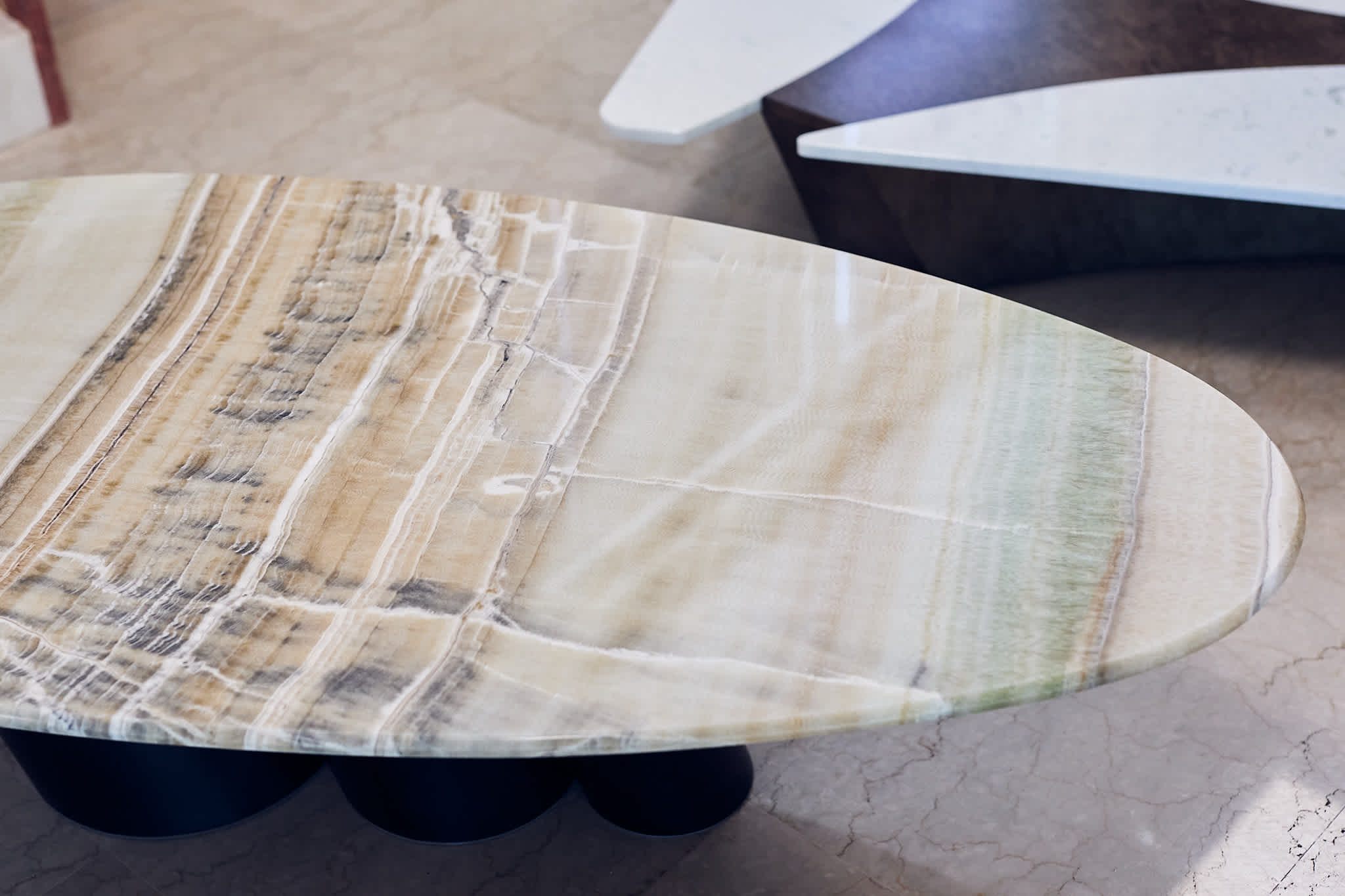

Simeg's "custom-made" philosophy is reflected in its showroom, which serves as a stone atelier. Here – much like fabric swatches in a tailor's – customers can explore a wide range of materials, finishes and colours, creating unique, custom projects. The gallery of sample settings offers inspiration and opportunities to experiment with stone in creative, engaging ways.

Simeg stands out through its deep commitment to environmental sustainability, which it demonstrates through innovative projects and major partnerships with designers at an international level. One such project, Stone Stuckers, is a clear example of the way the company strives to reduce its environmental impact through the recovery and recycling of waste materials. In addition, the Eccesso initiative further highlights Simeg's commitment to sustainability. Based on the assumption that every project leaves remnants of extraordinary, unique slabs of natural stone, the company has developed a programme to recover and use these materials in a creative manner, giving them a new lease of life by creating unique objects that combine natural stone with metal.

From a technical perspective, the company has invested in cutting-edge machinery such as bridge saws, waterjet machines and numerical control machining centres, which deliver precision and high finish quality. The choice of machines from Biesse’s Master and Primus series reflects the company’s focus on usability and operational efficiency, with suction cup systems that accelerate the positioning parts before machining.

"Biesse's products have served as a guarantee of excellent results and production continuity for us over the years, and we have been able to significantly reduce downtime and productivity losses."

Carlo Rotini, Operations Manager, SIMEG Marmi