Automation is at the top of the agenda for us

Nowadays, automating and digitalizing the business are at the top of the agenda for Ralph Fritz and his son, Florian. Besides a new hall, the glass specialists are also seeking to reorganize their production process to manufacture even faster and more efficiently.

As you enter the headquarters of Glas Fritz in Lörrach, you notice how they have managed to incorporate glass into their furnishings, alluding to the nature of their product line that heavily comprises glass for interiors.

These designers have high-quality glass products that go far beyond normal standards... “We want to offer our customers premium-quality glass products,” says Managing Director Ralph Fritz, speaking to GLASWELT.

The company also offers its products in small sets, although they frequently receive requests for mass customization. Florian Fritz adds: “We frequently use mass customization production for interior design and supply many small processing plants. We also provide consulting to customers for their glass-related questions. Personalized consulting is an important element of our services."

Automation: The key to success

For years, Ralph Fritz and his team have been positioning themselves as pioneers in automating production and in operations. “Only with an efficient manufacturing process and modern systems with the accompanying software can we face the challenges of today and tomorrow.”

One of Production Manager Matthias Hamann’s goals is to make cutting and processing fully automated, and many other processing stations, such as glass processing including milling and boring, have become increasingly automated for years.

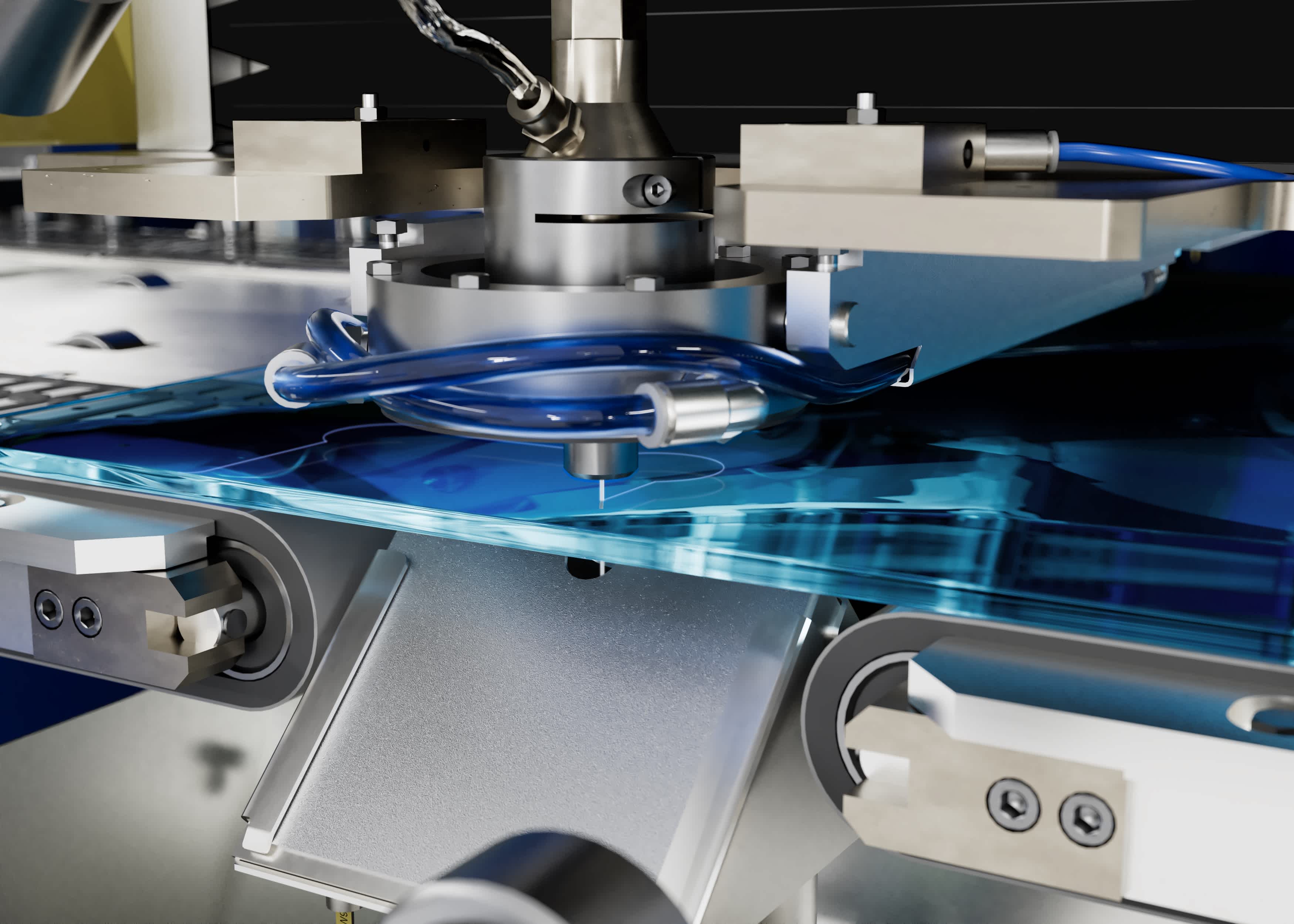

With that in mind, the Lörrach location recently invested in Biesse Glass’s machine technology again and purchased a second, powerful CNC boring and milling center with a Francesca waterjet.

Ralph Fritz: “To meet growing demand and to boost capacity, we have now purchased the second Francesca.”

And Production Manager Matthias Hamann adds: “Having two duplicate machines for processing also makes things easier for the employees. You can configure the machines and use them identically. And you don’t have to keep different spare parts on hand from different suppliers for maintenance either. Biesse delivers it all from a single source. Not only is this elaborate machine easier to use for the employees, but it also increases the efficiency of the processing procedures, as emphasized by the vendor, Biesse.

The Francesca horizontally oriented CNC machines at Glas Fritz perform any required work such as boring, milling, countersinking, and processing cuts and waterjet processing work on flat glass panes fully automatically and accurately. Furthermore, this also includes model panes.

At Glas Fritz, Francesca is used to process glass for shower stalls, partition walls, cabinets, and other interior glass, and for glass balustrades, among other things.

Francesca’s high productivity is due, among other things, to independent, multi-spindle heads that can simultaneously bore glass from above and below while processing at a high speed. In addition, it has turret heads that make it possible to change tools very quickly.

Furthermore, the Francesca series has advanced tool cooling and a safety system with a laser surface scanner. It also has integrated combination tool management, glass thickness monitoring, a DXF interface, and automatic tool measurement and bore grinding configuration. Francesca has a working depth of up to 2600 mm or 3300 mm and a virtually unlimited working length.

Production Manager Matthias Hamann: “There are no limits when positioning bores and cuts in the work area. You can even process glass formats that go beyond the machine’s working width. And the system’s optional glass thickness measurement also lets you automatically adjust countersinking depths, such as for flush-mounted fittings, improving the accuracy of the processing.”

What does Francesca do in detail?

With a clear focus on quality, innovation, and customer satisfaction, Gerhard Fritz GmbH has established itself as one of southwest Germany’s leading glass vendors. Their secret is delivering glass products with extraordinarily high quality.

“You need a motivated team of great employees and well-equipped machinery to deliver quality products,” emphasizes Ralph Fritz. “We have both. However, it is important to increasingly automate the work processes in the company, and we will continue to invest heavily in that. Automation is at the top of the agenda for us, and with it we will set the stage for a successful future.”