Compact and intuitive for instant productivity.

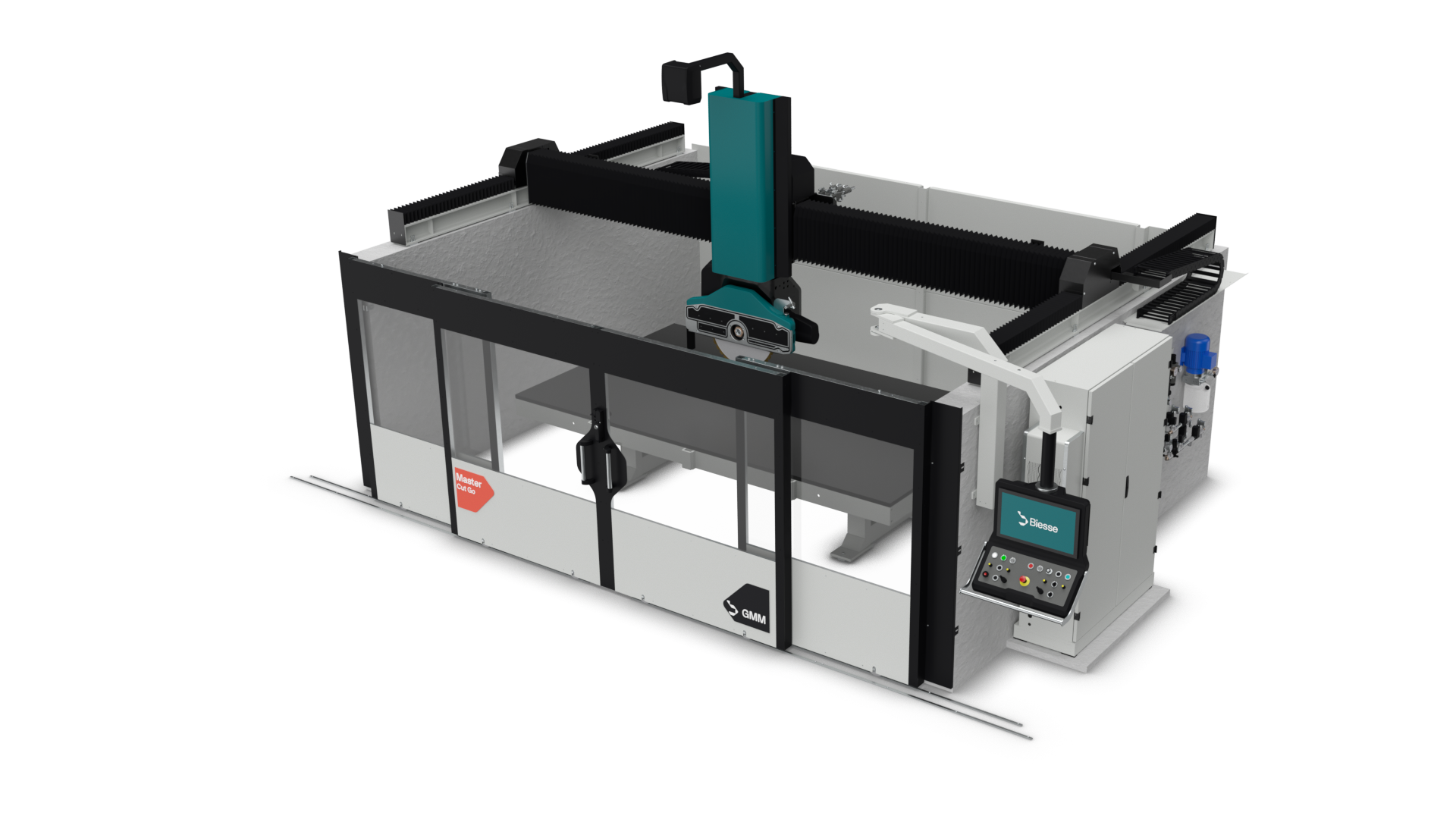

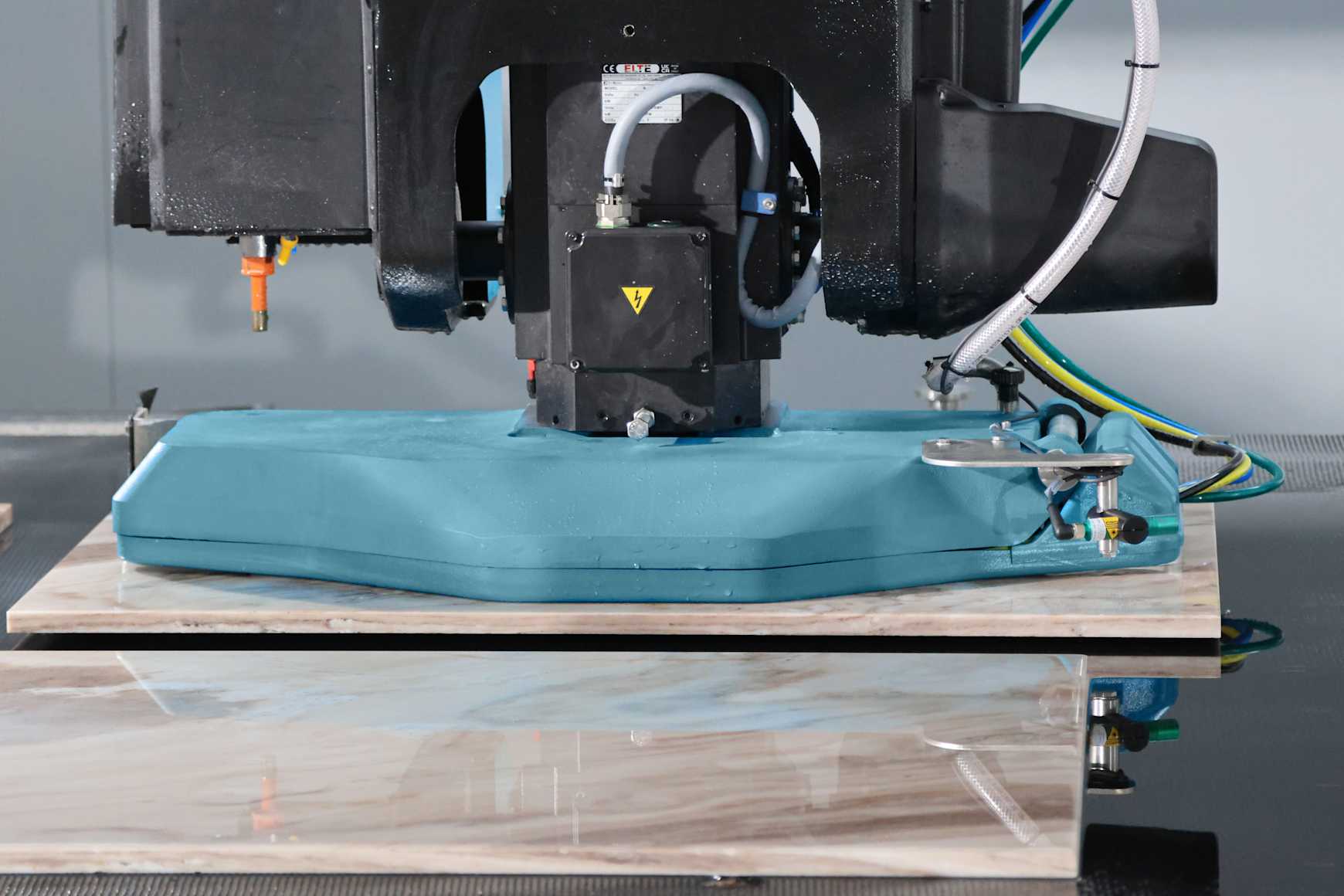

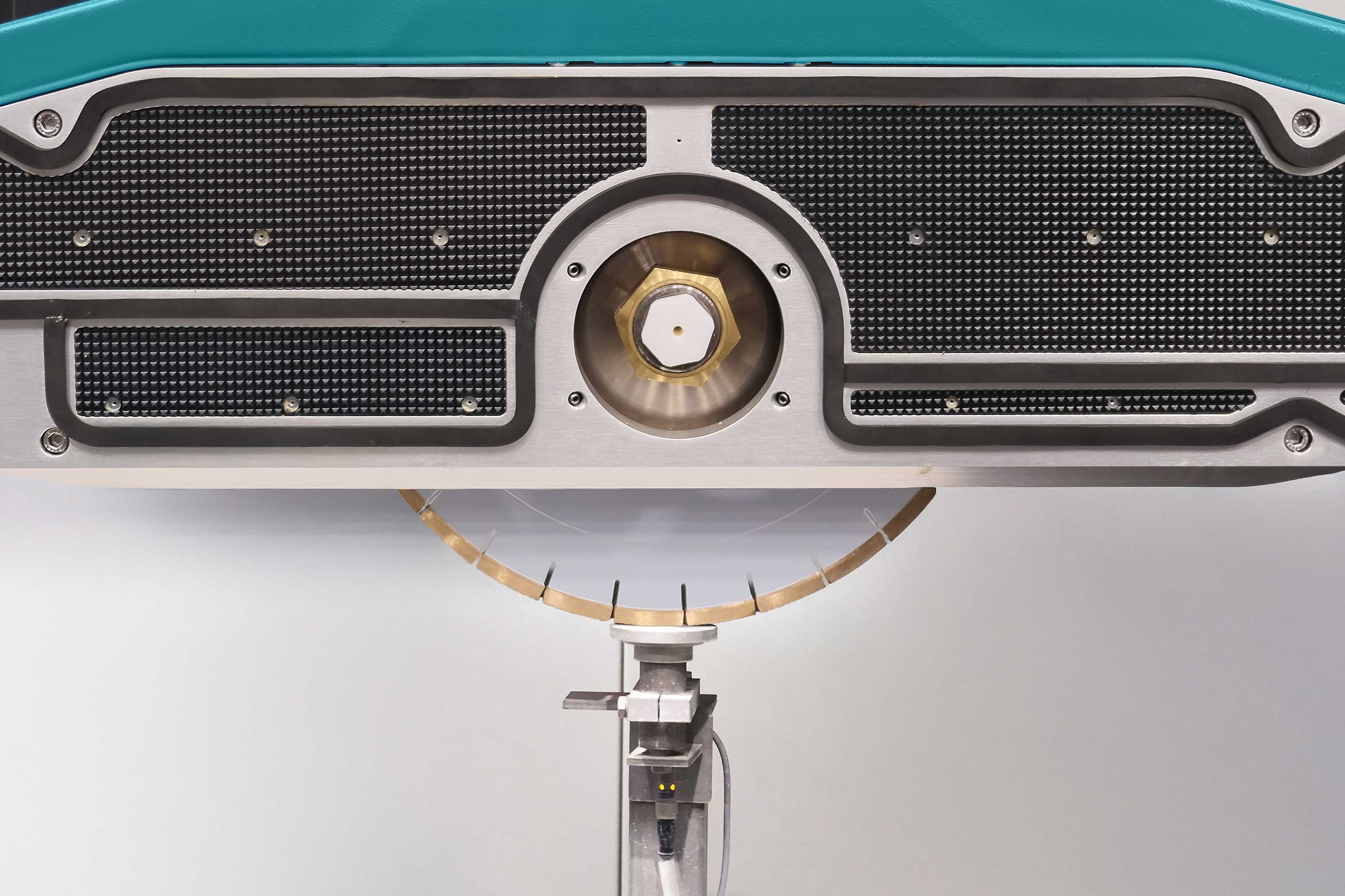

Master Cut GO C W is a compact and reliable 5-axis CNC sawing machine designed to ensure maximum ease of use. Its small footprint makes installation simple even where space is limited, offering a 480 mm Z-axis stroke and Ø 625 mm maximum blade diameter to support a wide range of cutting needs. The intuitive programming interface enables instant start-up and fast learning, keeping daily operations smooth even for less experienced users. Versatile and efficient, it is ideal for homeware and furniture production.

Control at your fingertips: smart, intuitive and ready to go. The 21″ ergonomic multitouch HMI is integrated into the machine controls, supported by GMM software designed to be simple, innovative and intuitive, enabling quick and efficient start-up of any stone-processing job.

The right tool, always ready. The 4-position Magnetic Tool Changer enables fast and precise tool swaps. Designed for milling and drilling, it is ideal for users working with a variety of tool diameters.

Main Technical Data

Sectors & Application