High performance. Fully adaptable.

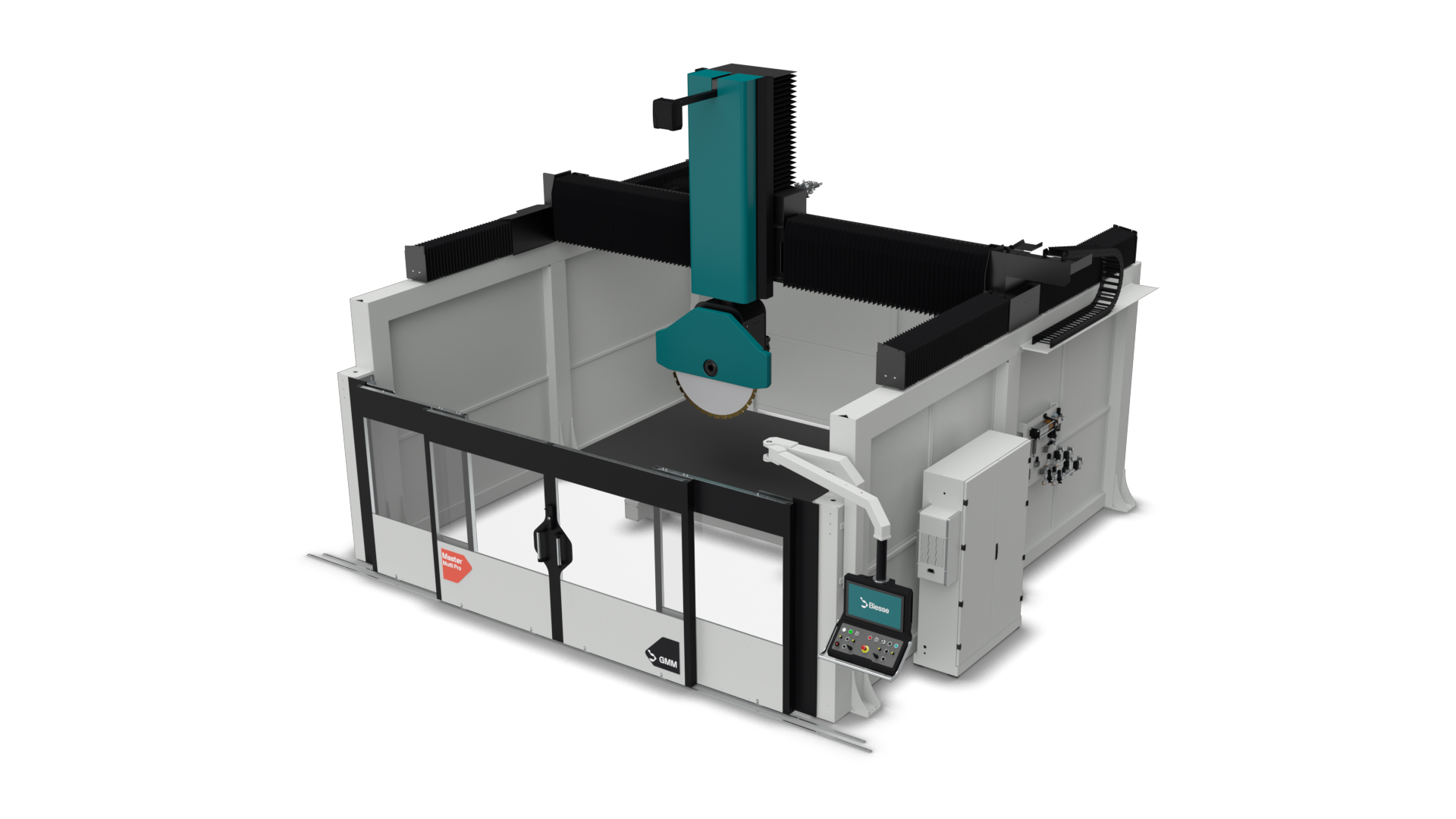

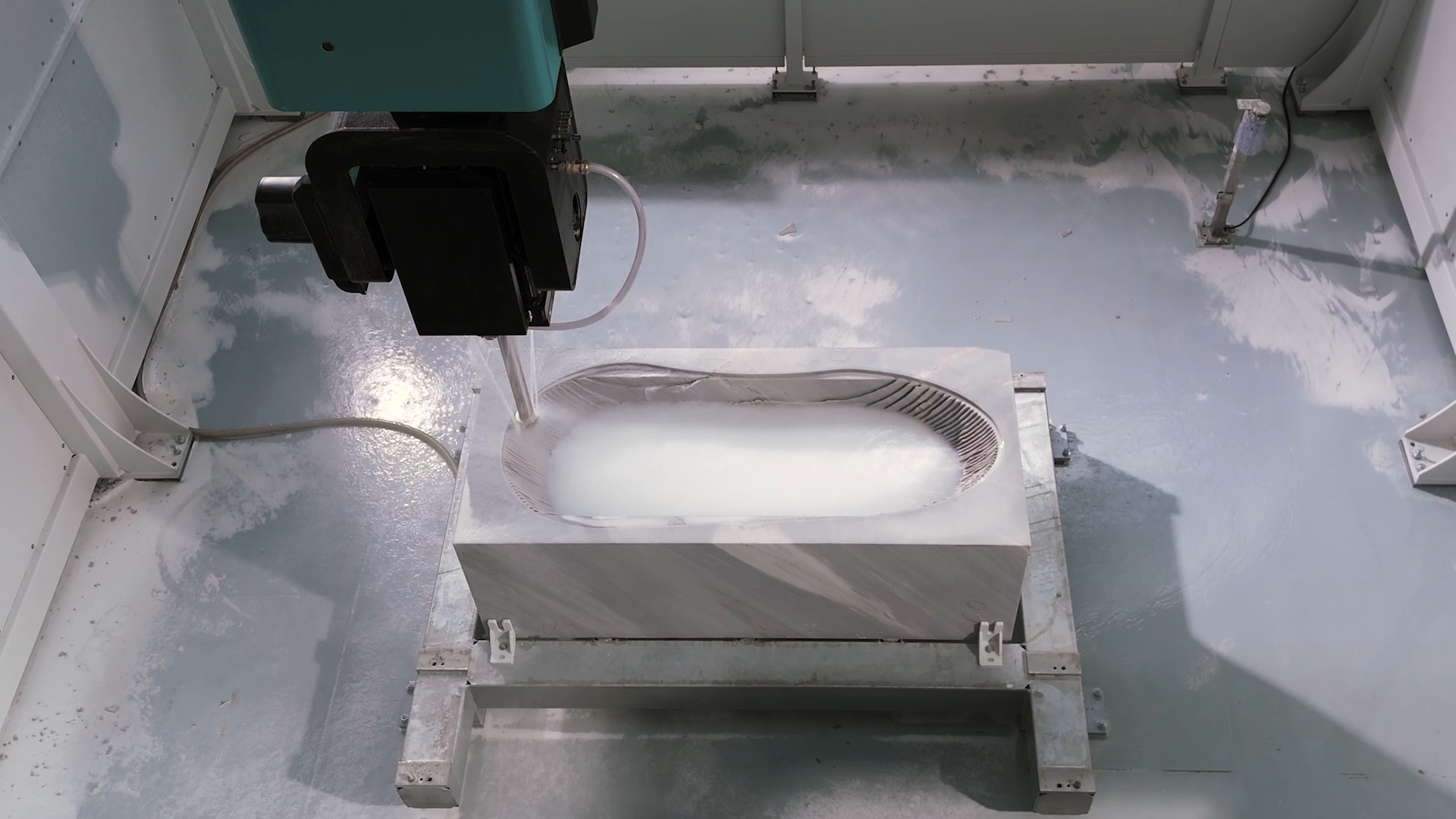

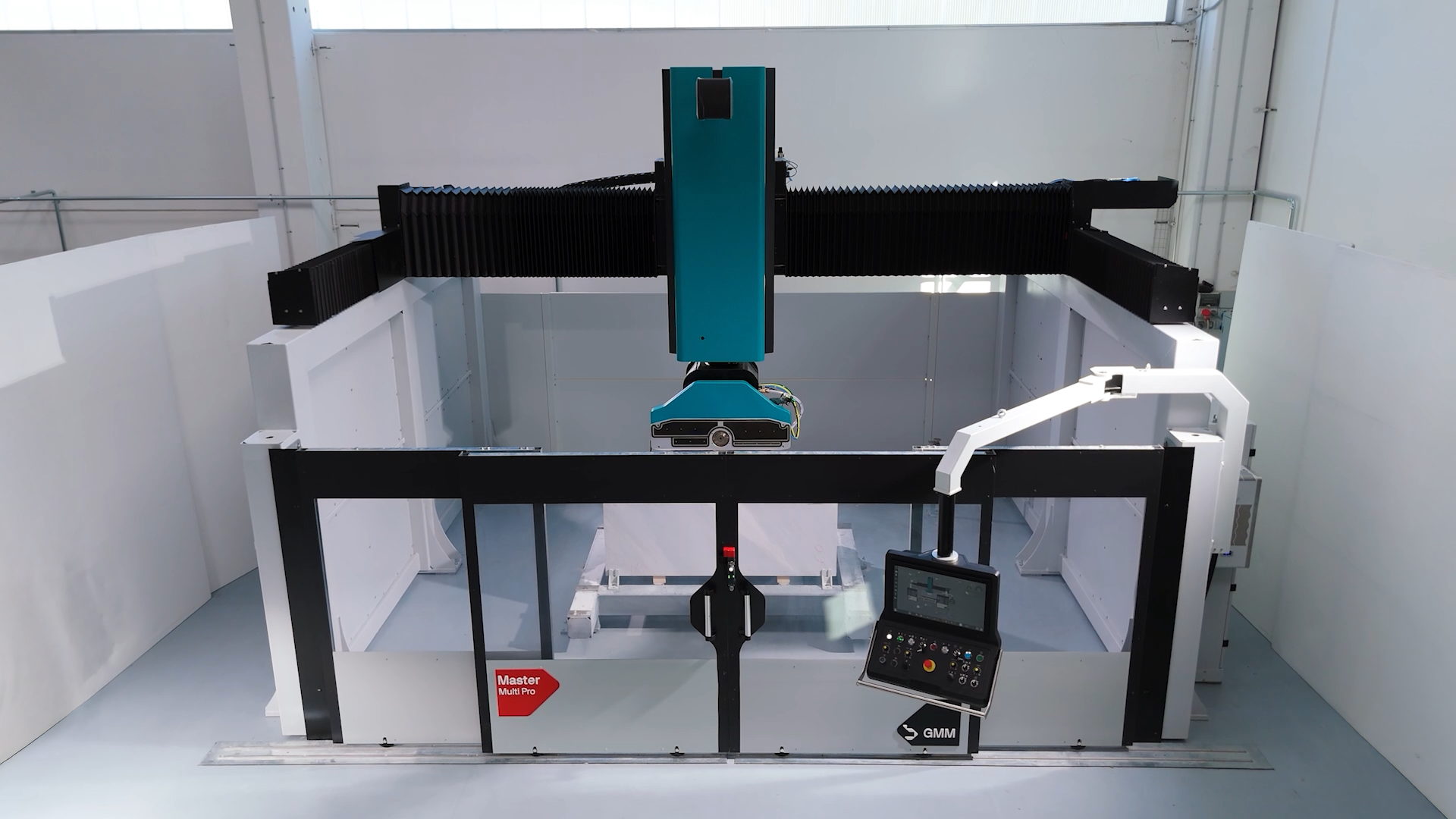

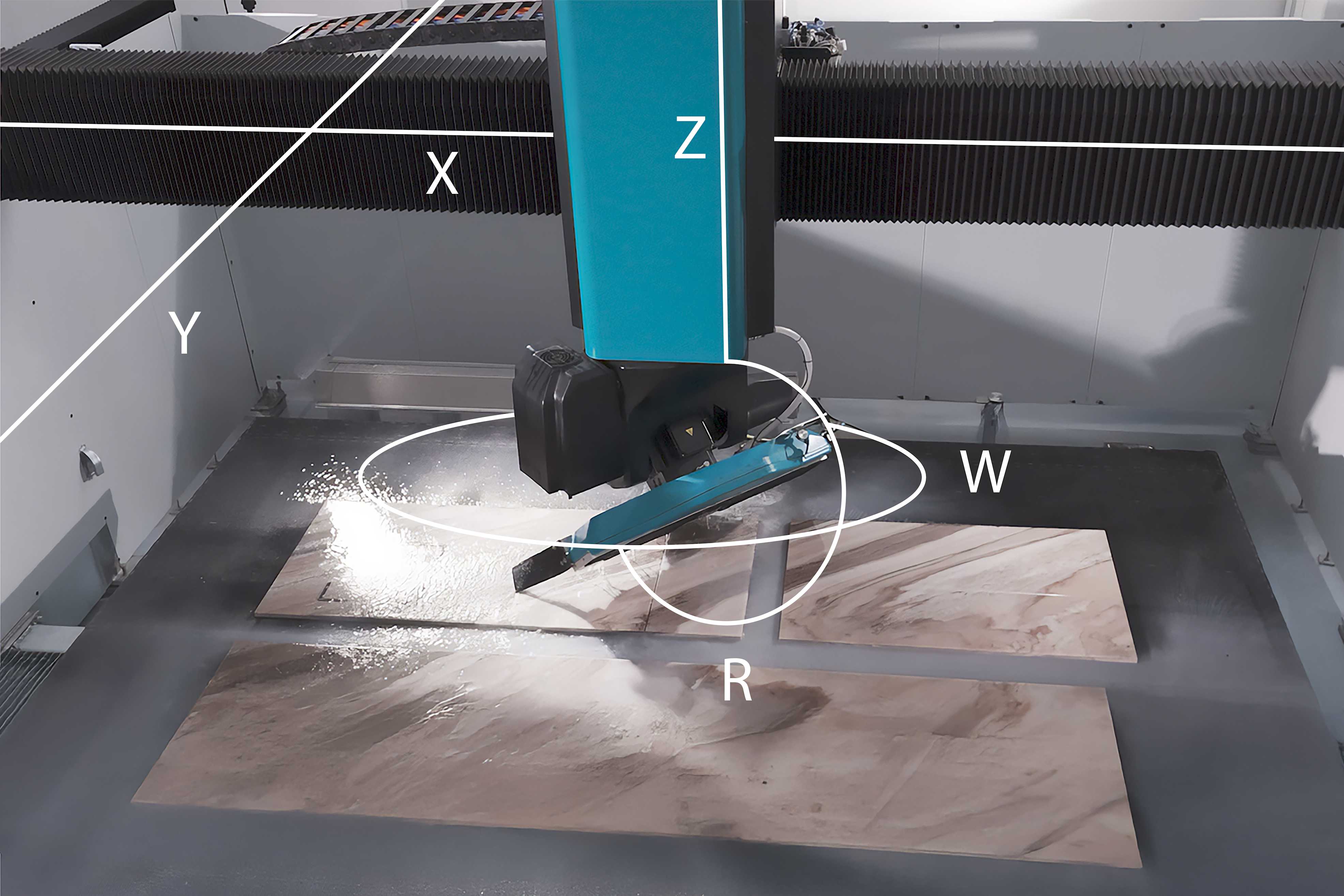

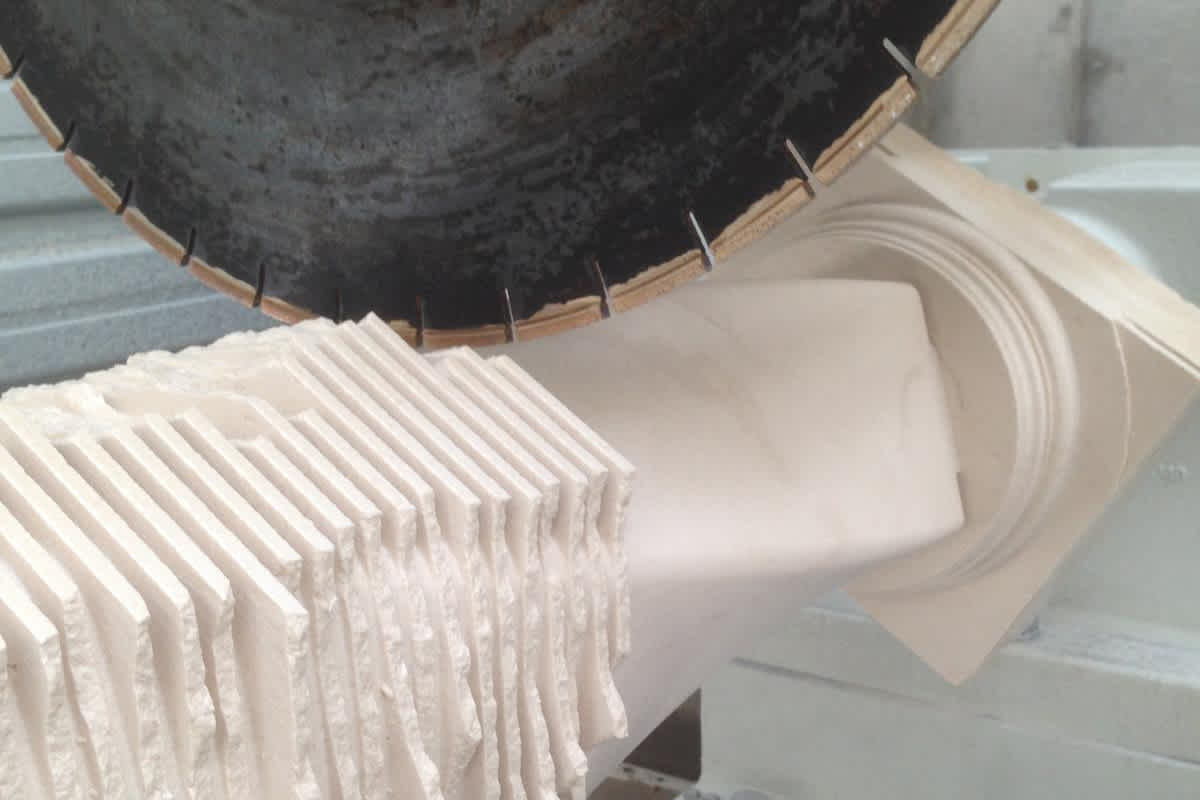

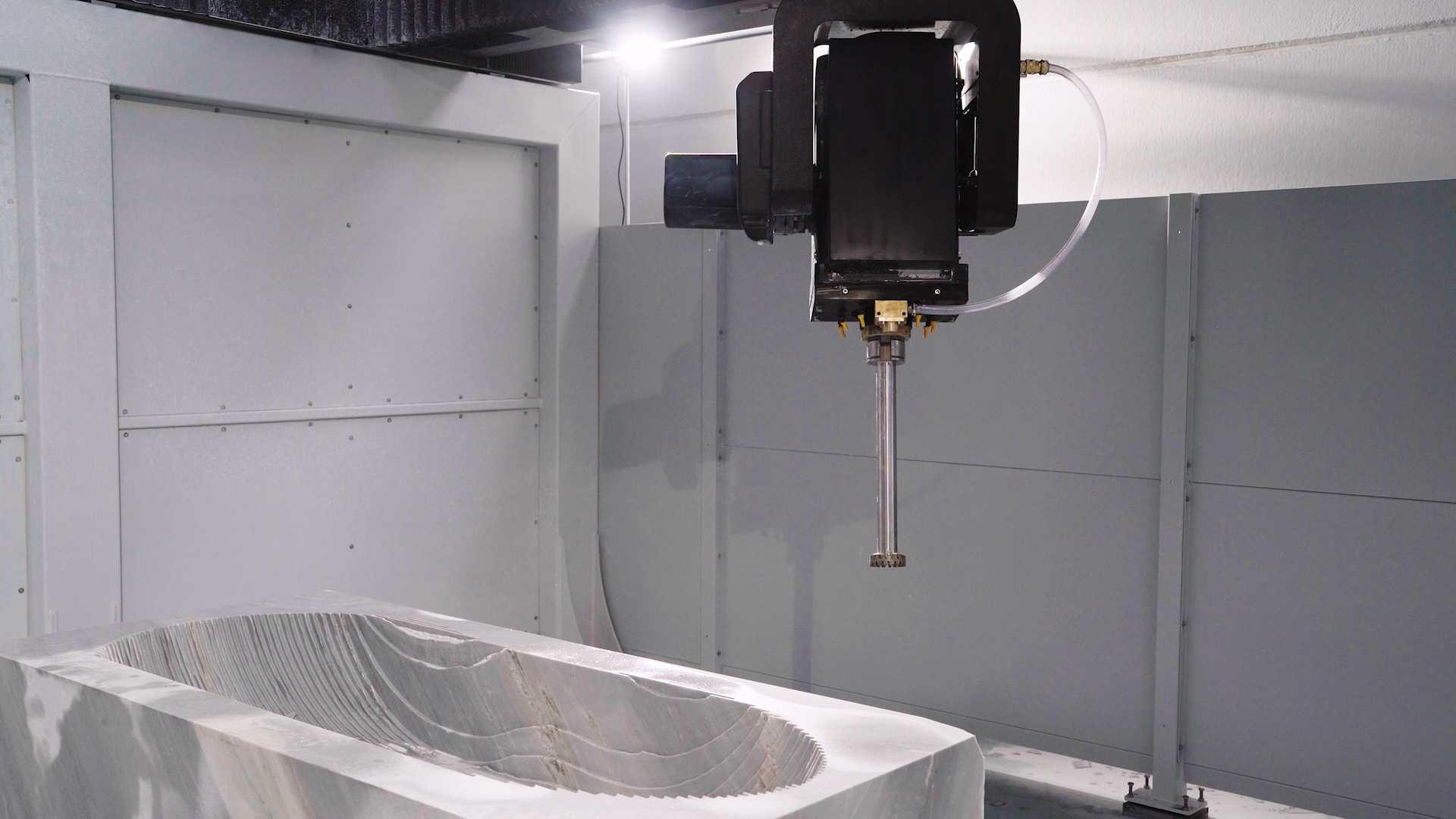

The Master Multi Pro S WT is a 5‑axis stone machining center for slabs and large blocks. Its robust structure and advanced 5‑axis head enable straight, inclined, curved, and 3D shaping operations. Highly configurable in layout and options, it adapts to any production need with precision, reliability, and performance.

Control at your fingertips: smart, intuitive and ready to go. The 21″ ergonomic multitouch HMI is integrated into the machine controls, supported by GMM software designed to be simple, innovative and intuitive, enabling quick and efficient start-up of any stone-processing job.

Smooth transitions for nonstop productivity. The automatic tool magazine, available with 12 or 24 ISO40/ISO50 positions, enables fast tool changes and keeps machining workflows efficient, even when handling large or heavy tooling setups.

Main Technical Data

Sectors & Applications