Inside Biesse Germany 2024: A huge success

It's already a tradition, the Biesse in-house exhibition at the Ulm campus. This year, the Inside took place on June 20 and 21, 2024, along with proven partners from the software and tool sectors. The numerous visitors were inspired by a wide range of innovative technologies in the fields of wood, glass, stone and plastics. The workshop, which this time focused on the topic of formwork construction, was, as always, a well-attended highlight.

505 scoops of ice cream - the summer edition of Inside really lived up to its name and many of the guests enjoyed Italian ice cream creations or Swabian dishes from the food truck between informative consultations and interesting demonstrations. However, the focus of interest was naturally on the smart machine solutions from the Pesaro-based manufacturer.

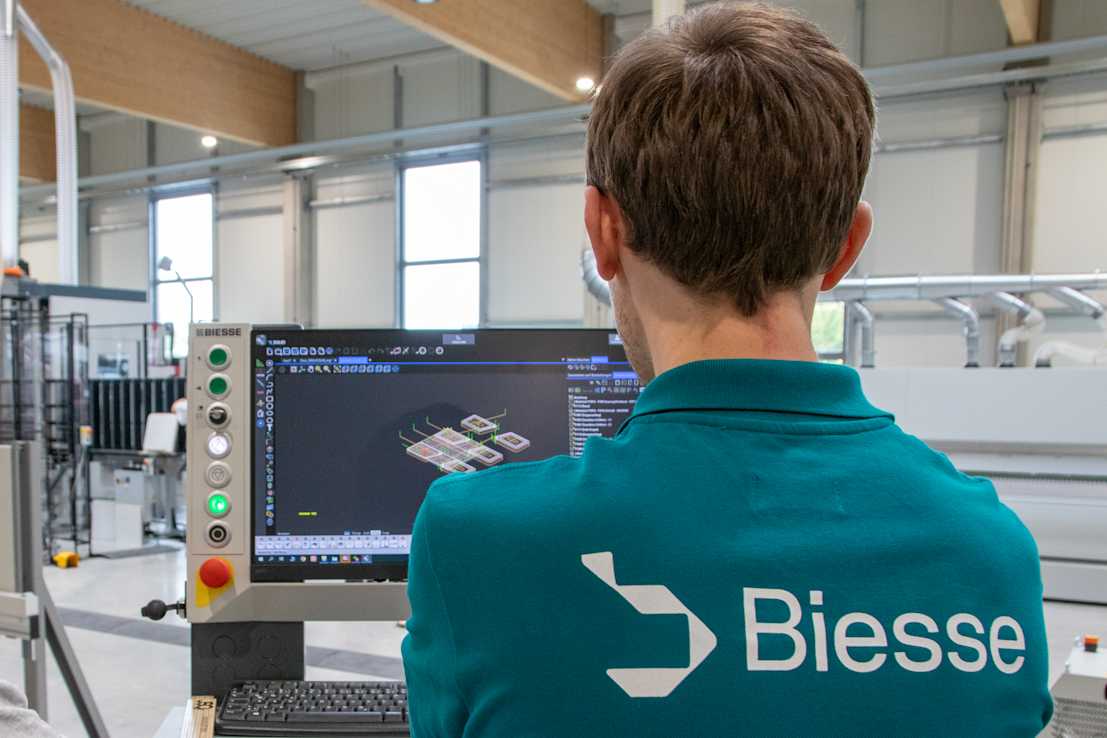

The competent audience took the opportunity to inform themselves extensively about future-oriented machines and systems in combination with innovative software in the fully equipped showroom at the German head office in Nersingen. The CNC topic played an important role - and was therefore one of the main focuses of the trade fair. The Rover A machining center, which was running at full speed, demonstrated the current state of the art and the many possibilities of flexible CNC machining in three versions: a free-standing console machine, a high-speed machining cell and a flat table version for nesting operations. In addition, the established storage-saw combination - the Selco panel dividing saw with the Winstore panel storage system - attracted a great deal of interest due to the time savings resulting from the automation of production processes. The “new one” in the showroom also attracted particular attention: the Brema Vektor vertical processing cell with return system has a compact set-up area and yet provides high performance.

“Our experts were able to address the trade visitors' questions in detail during the in-depth consultations and provide them with many suggestions for optimizing and automating their production. We received a lot of positive feedback from customers.” As Head of Marketing for the German-speaking region, Katharina Schaf was of course on site to feel the market's pulse directly and to intensify contact with guests and partners.

Highlight: Workshop

This year, woodworkers with an affinity for construction were able to discover the art of producing and using special formwork for casting concrete in an exclusive workshop. Together with the software specialists from moldtech and Direkt CNC-Systeme, Biesse offered the well-attended seminar “Made easy: formwork and precast concrete parts for buildings, staircases and furniture construction”. The participants took the opportunity to experience the effective and modern production of customized formwork in the form of a stool with 3D relief and lettering as well as a staircase formwork with in-situ concrete. “These forms are often produced by formwork manufacturers or joineries and are used in building construction. As showroom manager Samuel Schaefer explains competently, “The term in-situ concrete is used for components that are concreted ‘on site’, i.e. in the classic production method with the aid of a formwork into which the concrete is poured and where it sets.” Nesting is a major and important topic here, as Schaefer discovered in many conversations during the in-house exhibition: “A machine that can do everything is what many users want - and this can certainly be fulfilled with Biesse's extensive portfolio”.