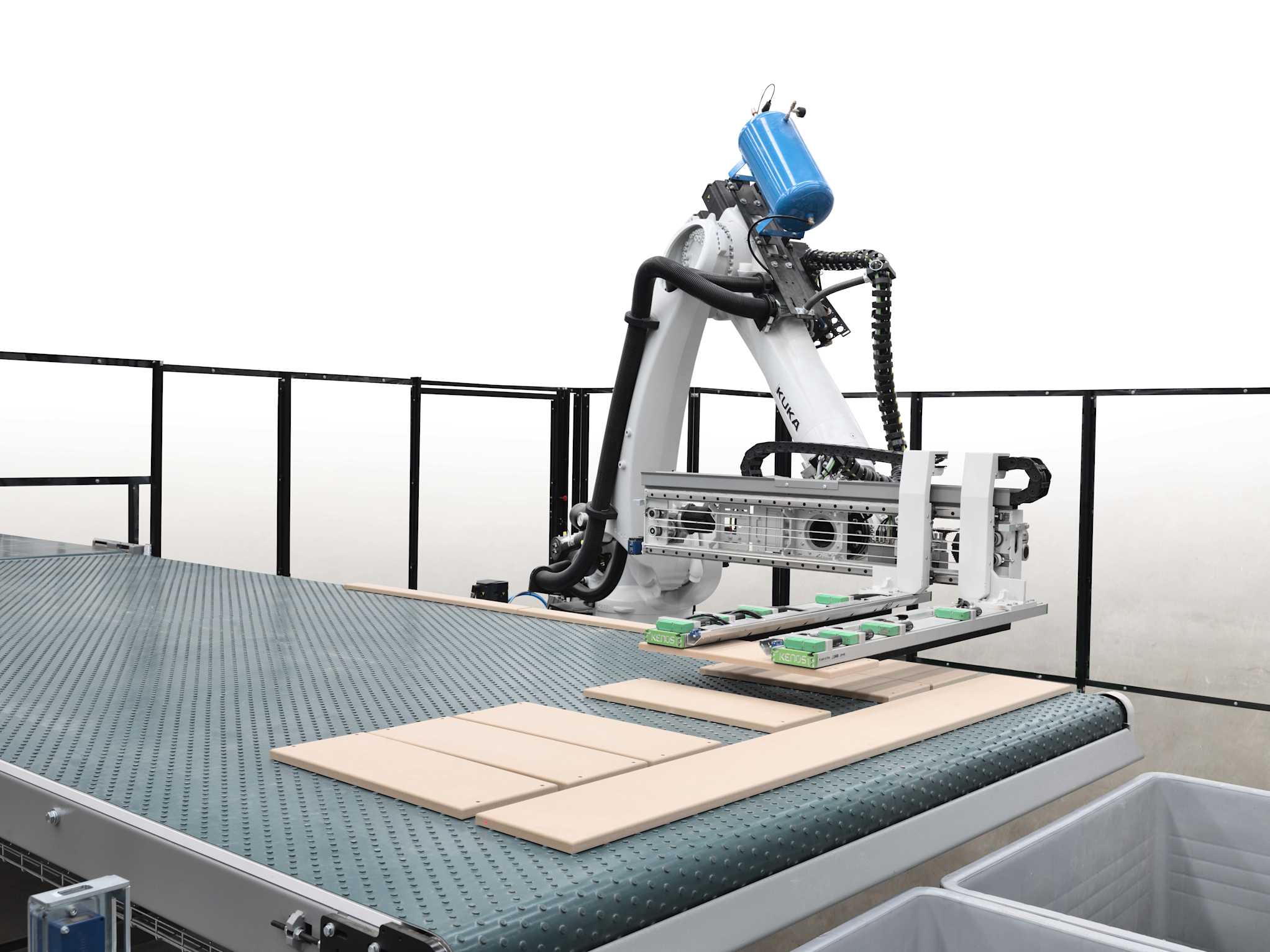

Automation, optimisation, productivity and quality are the key words of “Ros Ft”, the new Biesse robotic system for flexible unloading.

In a manufacturing environment that is evolving at speed, automation is crucial in order to increase efficiency, precision and overall production. Within this context, Biesse has once again exceeded its own limitations with the innovative robotic system for flexible unloading, known as ROS FT. This cutting-edge system has been developed to revolutionise the unloading process of machined parts from nesting machines, offering unparalleled speed, precision and adaptability.

Why rely on ROS FT for unloading operations?

“The Biesse Ros Ft system represents a significant leap forwards in the integration of automated technologies in the production process. By tackling the challenges associated with unloading machined parts from nesting machines, this robotic system not only boosts efficiency and accuracy, but also sets new standards for adaptability within a production environment that is constantly evolving,” explained Giovanni Battista Pizzoferrato, Technology Application Manager for the Italian market.