The interaction between stone and 4.0 technology

The technological harmony of Biesse and Diamut - key players at “Italian Stone Theatre”.

At the “Italian Stone Theatre” event that took place during the 2017 Marmomac, the technologies of Biesse and Diamut demonstrated the potential for stone machining, highlighting the productive and technical ability of the furnishing and design companies involved - Seguso Gianni and Vicentina Marmi. The event was sub-divided into a number of exhibitions where Biesse and Diamut were the stars of the Virtuous Machines section organised by designer Raffaello Galiotto.

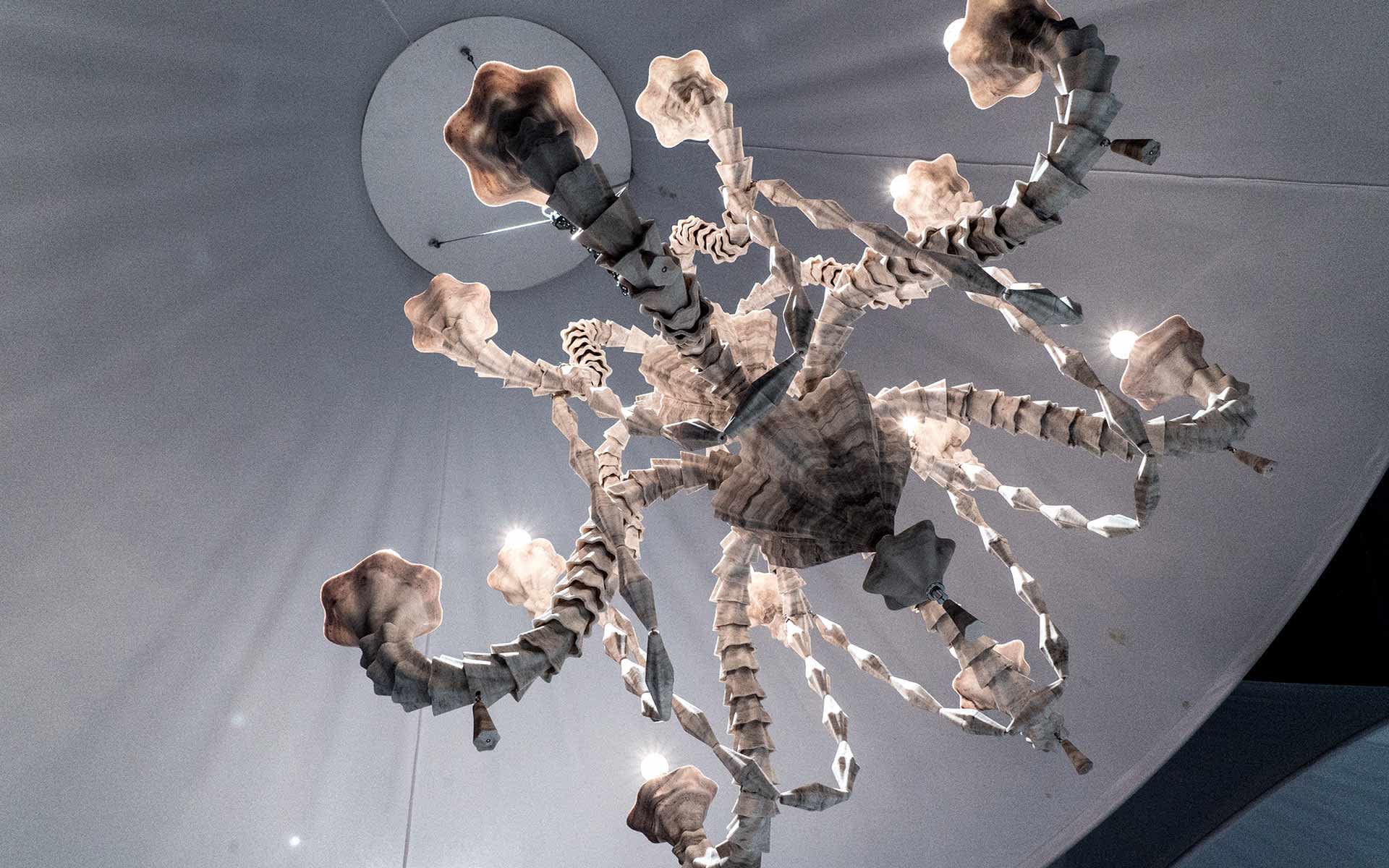

Two projects were even transformed into prototypes: “Rezzonico” and “Easy” - design items that seem to be ready for large-scale production and marketing. As the designer explained, «The 'Rezzonico' lamp is produced using a natural veined marble - a choice that highlights the value of natural materials, granting this serial format a unique quality that it wouldn't otherwise have. Each single lamp can be considered a unique item because its natural pattern is unrepeatable. From a technical viewpoint, the 5-axis waterjet machining of the Primus was brought to new levels, considerably limiting the waste.» The work was produced in collaboration with Generelli Marmi. «The use of the waterjet technology of Biesse's Primus range emphasised the amazing possibilities to transform stone materials into artefacts that are rather complex in both the technical and formal sense. The latest systems used on these machines guarantee accuracy, working speed and reduced waste; these factors are crucial for the large-scale production of practical objects with a complex shape, and for reaching performance levels similar to those of other, lighter materials.» This was the opinion of Matteo Generelli, company owner, after the prototype had been created.

From a technical viewpoint, the 5-axis waterjet machining of the Primus was brought to new levels, considerably limiting the waste.

Raffaello Galiotto - Designer

The second project, Easy, involves the production of bathroom furnishing elements, washbasins and bathtubs consisting of overlapping, interlocking parts with reduced use of materials and shorter milling times. Material savings: this was a vital point to ensure, and also the starting point for Diamut when it came to developing the technologies behind Easy - a work in “Palladio Moro” (an artificial marble agglomerate) produced with the help of Vicentina Marmi, DDX and Santa Margherita.

A somewhat rigid and challenging concept for the Diamut tools that had the colossal task of shaping a piece with truly modern lines; unusual dimensional tolerance values, and diamond grains painstakingly studied by the specialists of a company that can boast professionalism and skills built up over more than 30 years. The Vicentina Marmi team was satisfied with the outcome: "Diamut proved to be the winning solution, meeting the strict performance requirements and fully respecting the essential project requisites."