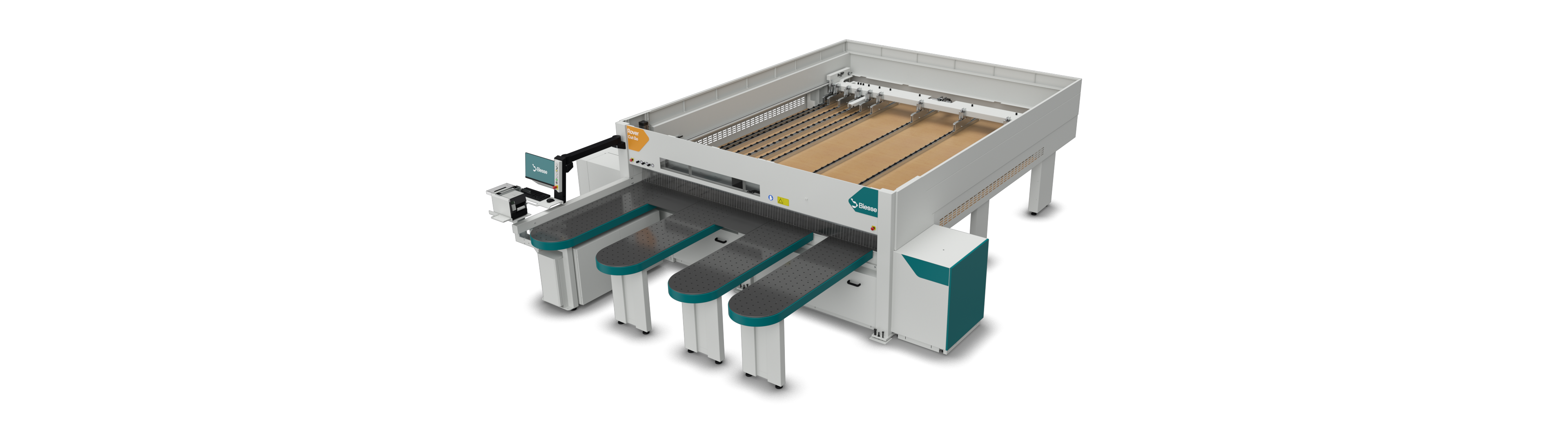

Rover Cut Go S F

Compact efficiency: empowering small craftsmen every day

Panel sizing machine for small craftsmen, designed for daily small-batch production. Combination of compactness and efficiency to serve the operator. Perfectly adaptable for use in confined spaces due to its compact footprint. Its easy configurability allows it to meet the specific needs of the operator, providing the ideal balance of precision and flexibility.

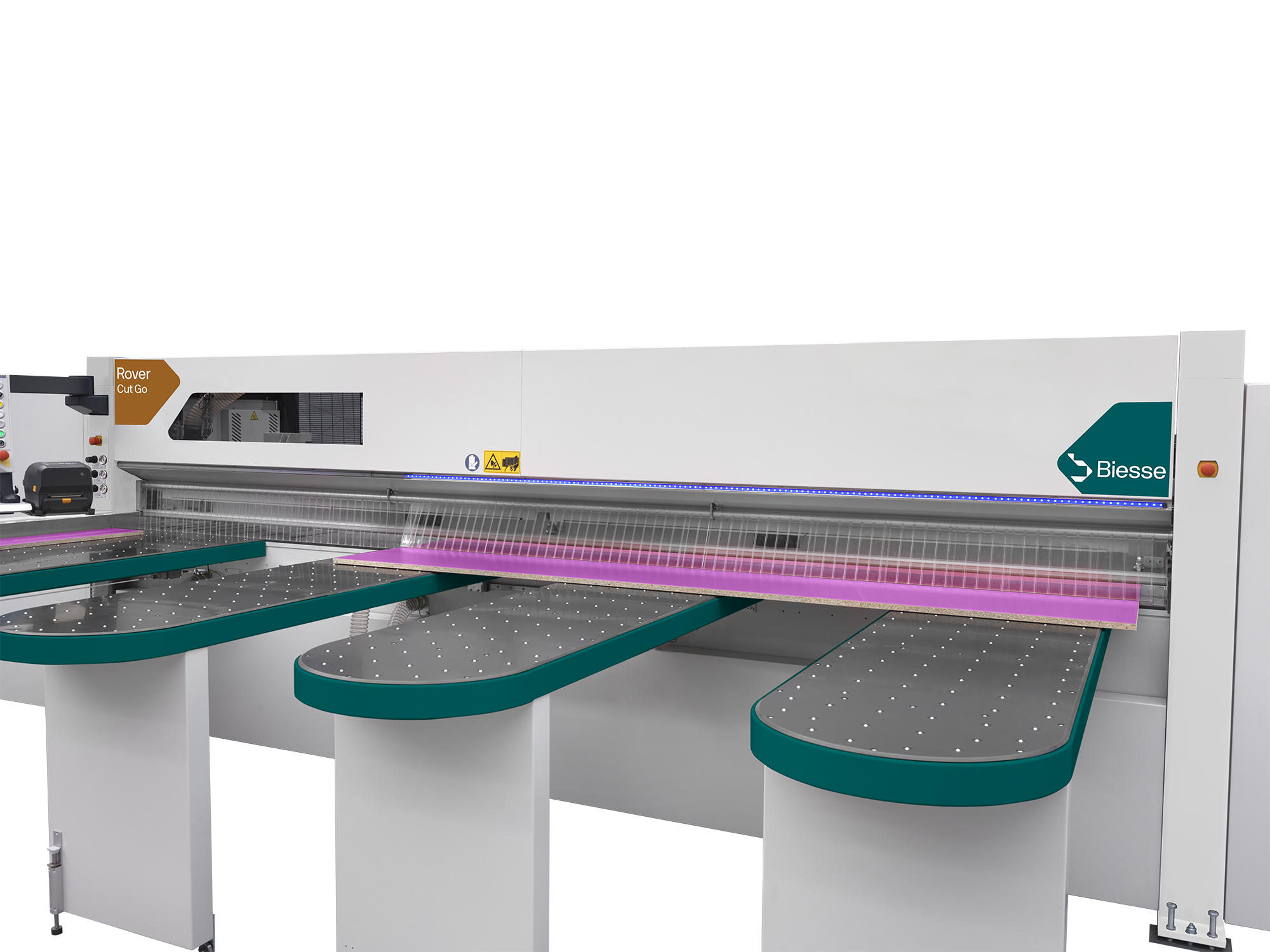

Optimal use of working area

Working area is designed to use all available space. Cross cuts are done on the square fence side, rip cuts on the opposite. Executing consecutives cuts on opposite sides of the cutting line, always guarantees enough room for the operator to handle panels with ease, without extra-movements.

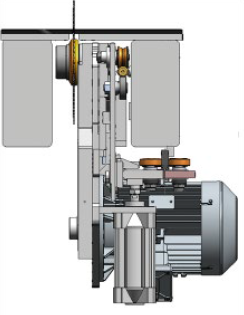

Sharp blade positioning

Main and scoring blade are driven by two independent motors, with a linear guides system

for their movement, granting perfect control on position and ensure cutting quality on each material.

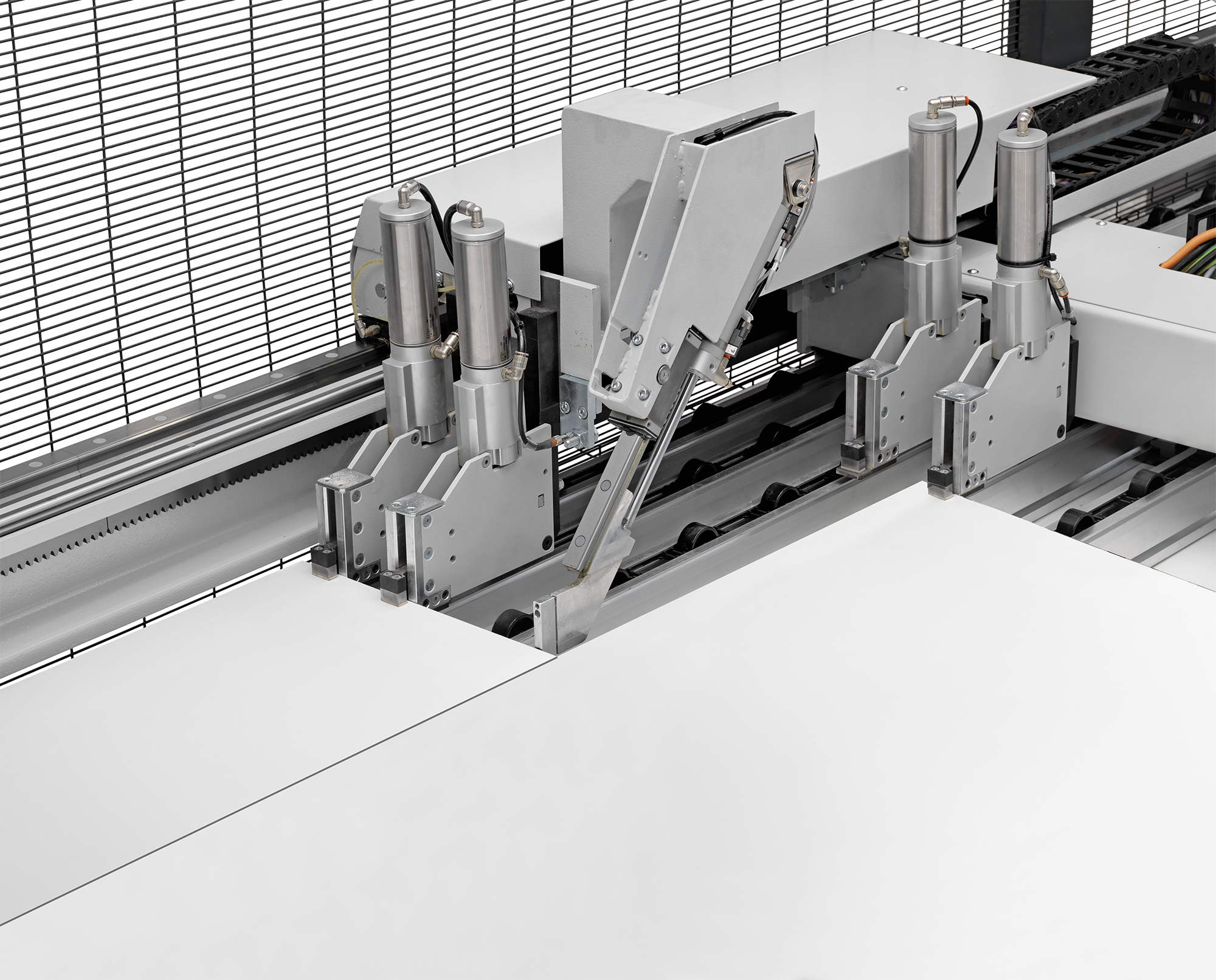

Productivity increase up to +25%

Twin Pusher 1.2 system enhances machine’s productivity and flexibility by efficiently managing

different sub-formats with a single cut.

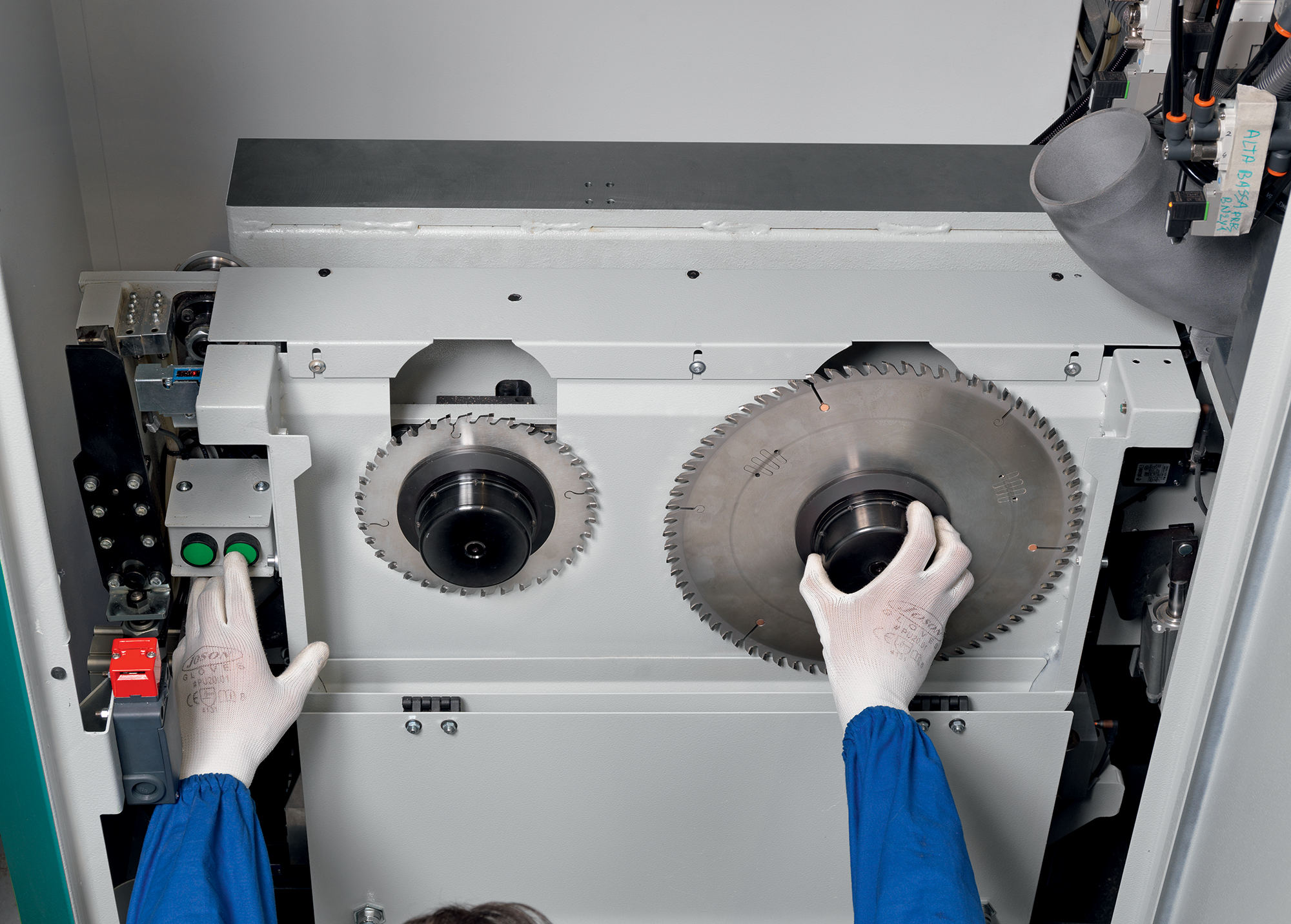

Zero-time blade changing

Quick blade change is the fastest tool-changing system on the market. Operator can easily change blades with the press of a button and no additional tools.

Extra storage, no extra footprint

Utilizes the space under the machine without increasing footprint.

Optimal use of working area

Working area is designed to use all available space. Cross cuts are done on the square fence side, rip cuts on the opposite.

Executing consecutives cuts on opposite sides of the cutting line, always guarantees enough room for the operator to handle panels with ease, without extra-movements.

Save on your daily consumption

Up to 80% saving on air consumption thanks to optimized dust extraction and additional power saving with automatic stand-by mode.

Saw blade carriage concept and side aligner

Compact and balanced structure ensuring max integrity over time, combined with an integrated

side aligner to grant perfect panel alignment on square fence.

Main technical Data

Sectors & Applications

Home & Office Furniture

Kitchen furniture

Retail & Contract

Customer Care

Personalised solutions, quick and efficient answers, and digitalised experiences for immediate satisfaction