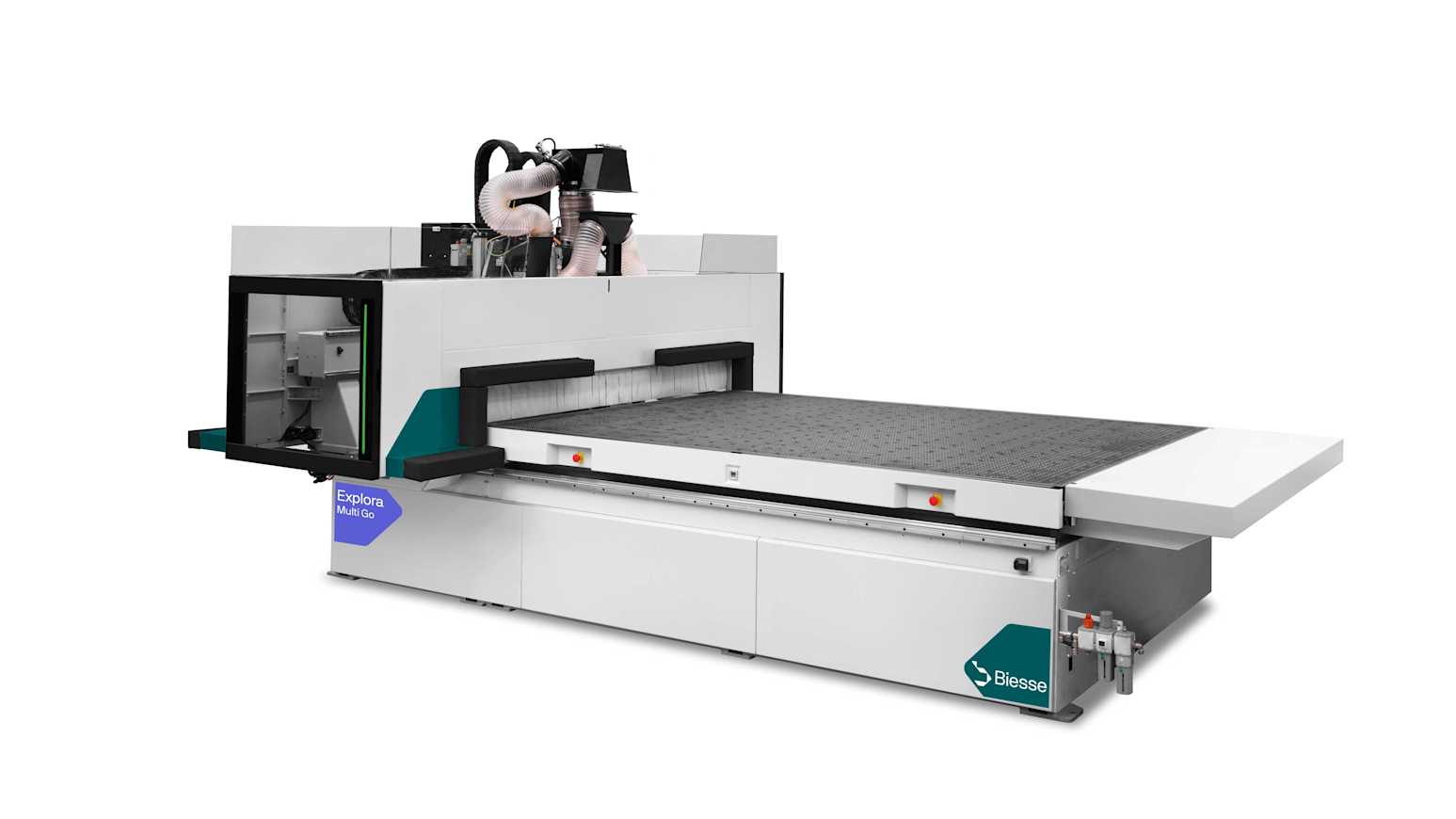

Explora Multi Go N K

Quality as target

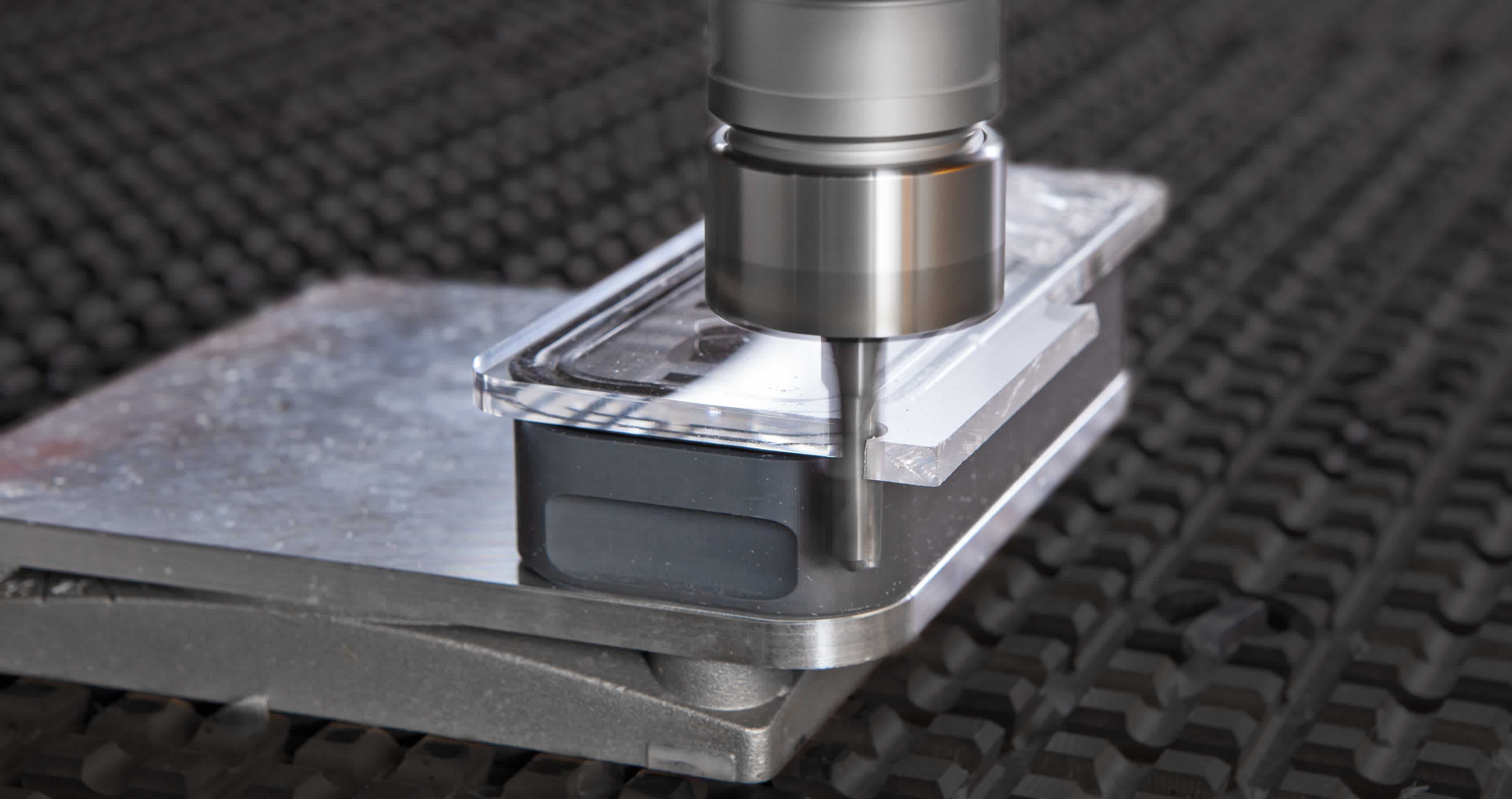

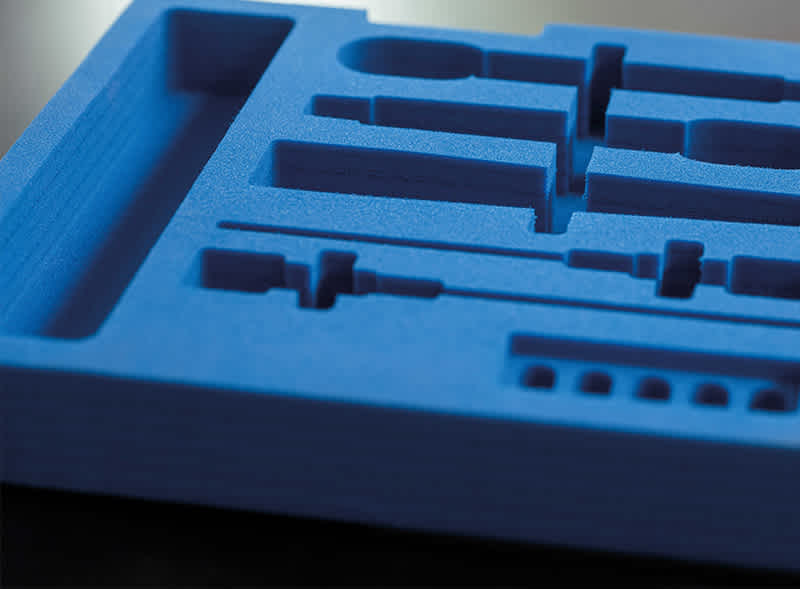

Finished parts are produced with high precision, minimizing errors throughout the machining process.

Designed for plastics, composites, and other non-ferrous materials, this CNC machine ensures maximum repeatability and consistent dimensional accuracy for every component.

Easy and fast maintenance

The machine is designed for exceptional reliability and user-friendly maintenance, minimizing downtime and reducing operational costs.

Robust spindles built for any condition

Liquid-cooled HSK F63 electrospindles, available in 9 kW or 19 kW, provide robust performance under all operating conditions.

From design to production

From CAD-CAM to finished piece, with this automatic CNC machine.

Interactive 3D simulation allows for production time calculation and improved planning, keeping costs under control."

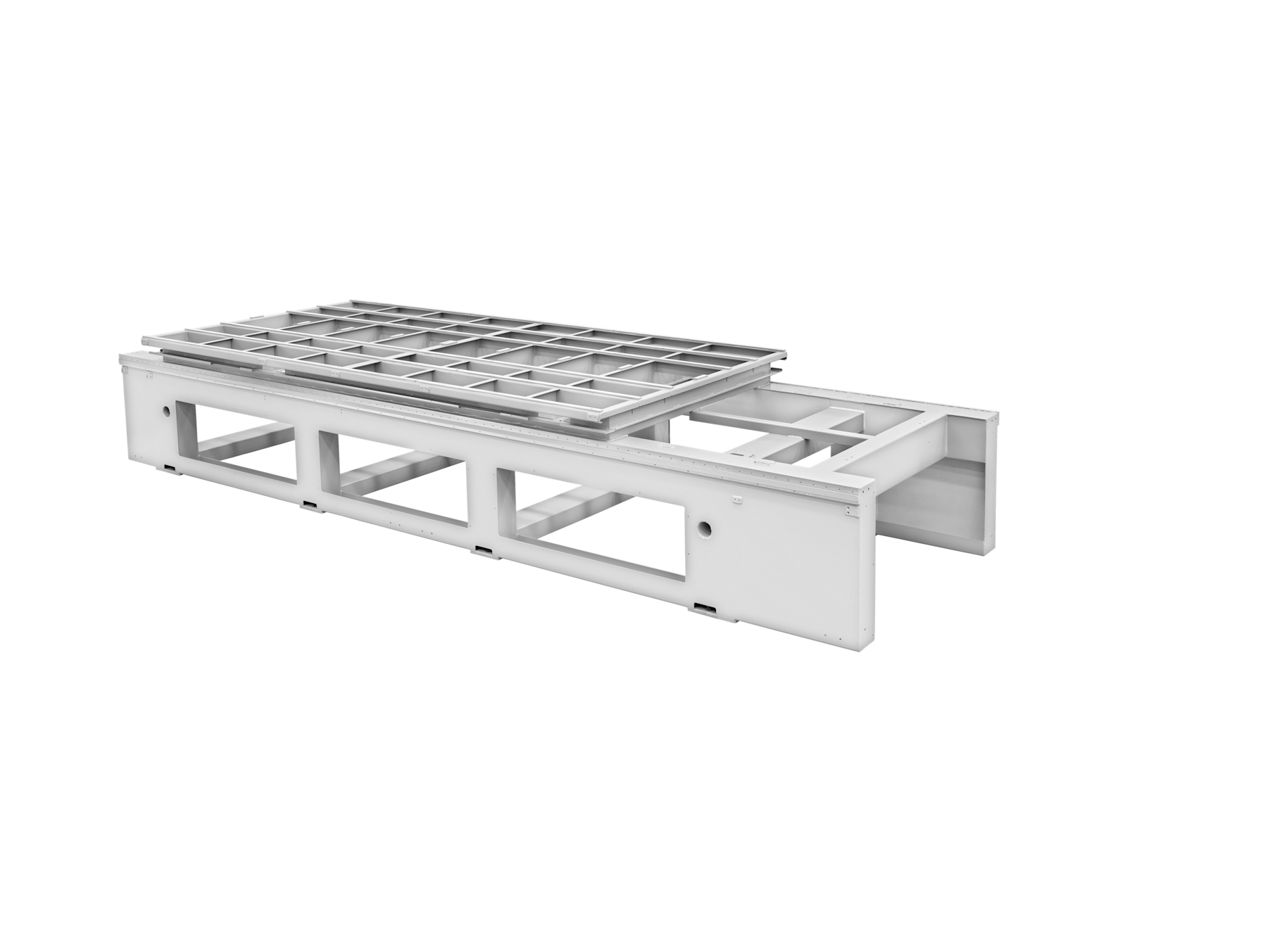

Robust structure

Explora Multi Go N K features a robust, well-balanced structure designed to handle demanding machining operations without compromising product quality.

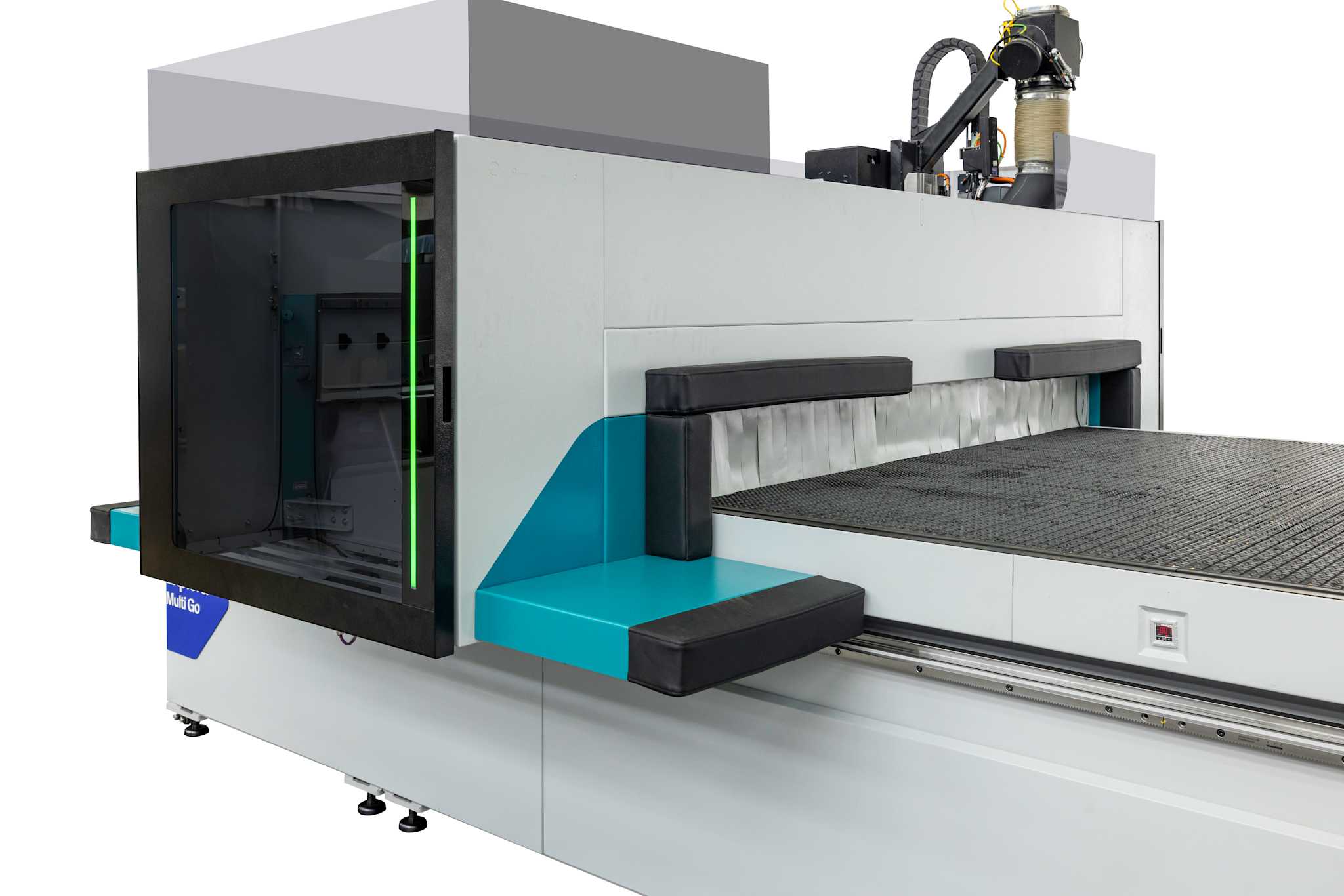

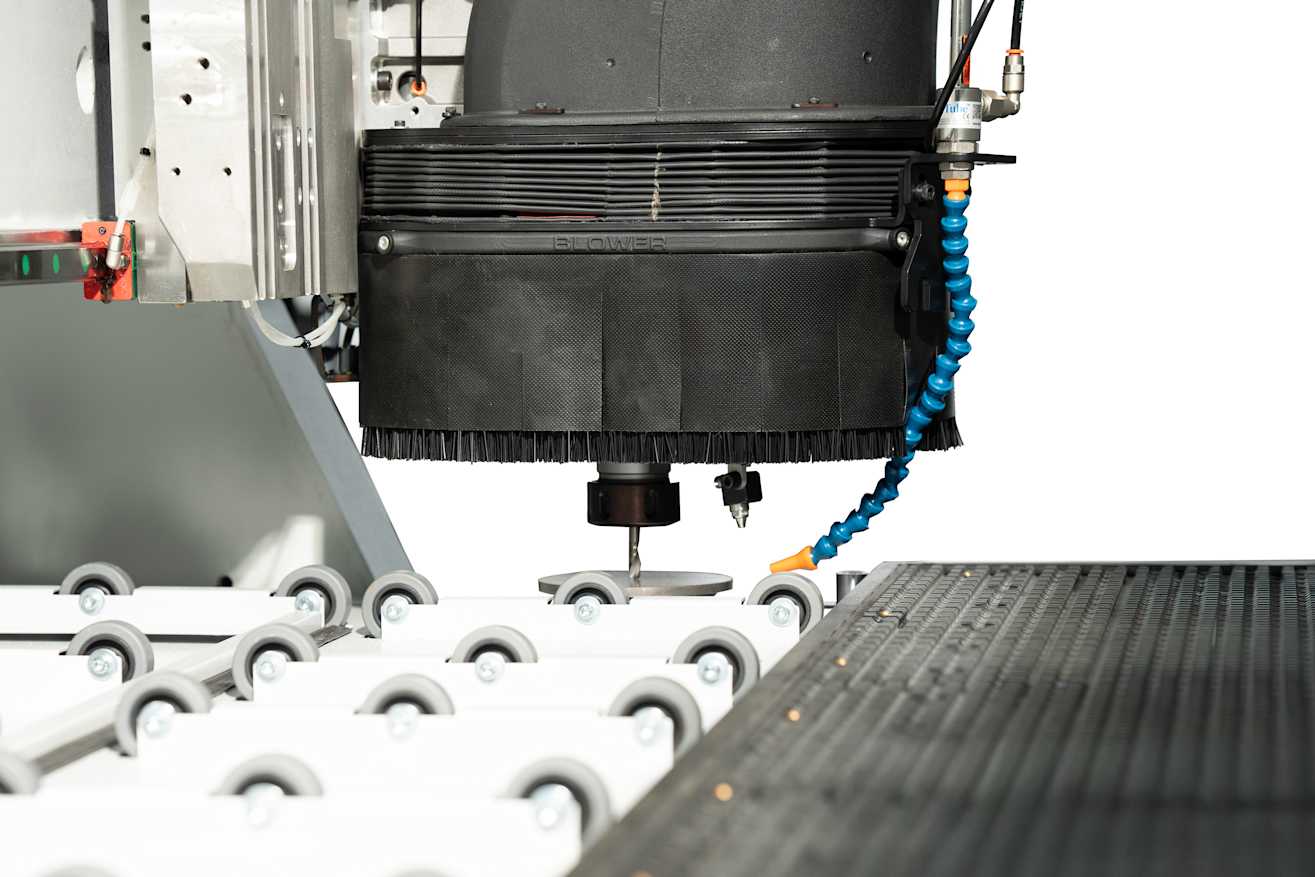

Cnc-controlled suction hood

The 6-position suction hood, programmable via the CNC, can adjust automatically based on tool length or manually by the operator according to sheet thickness, improving dust extraction efficiency and protecting the machine’s components.

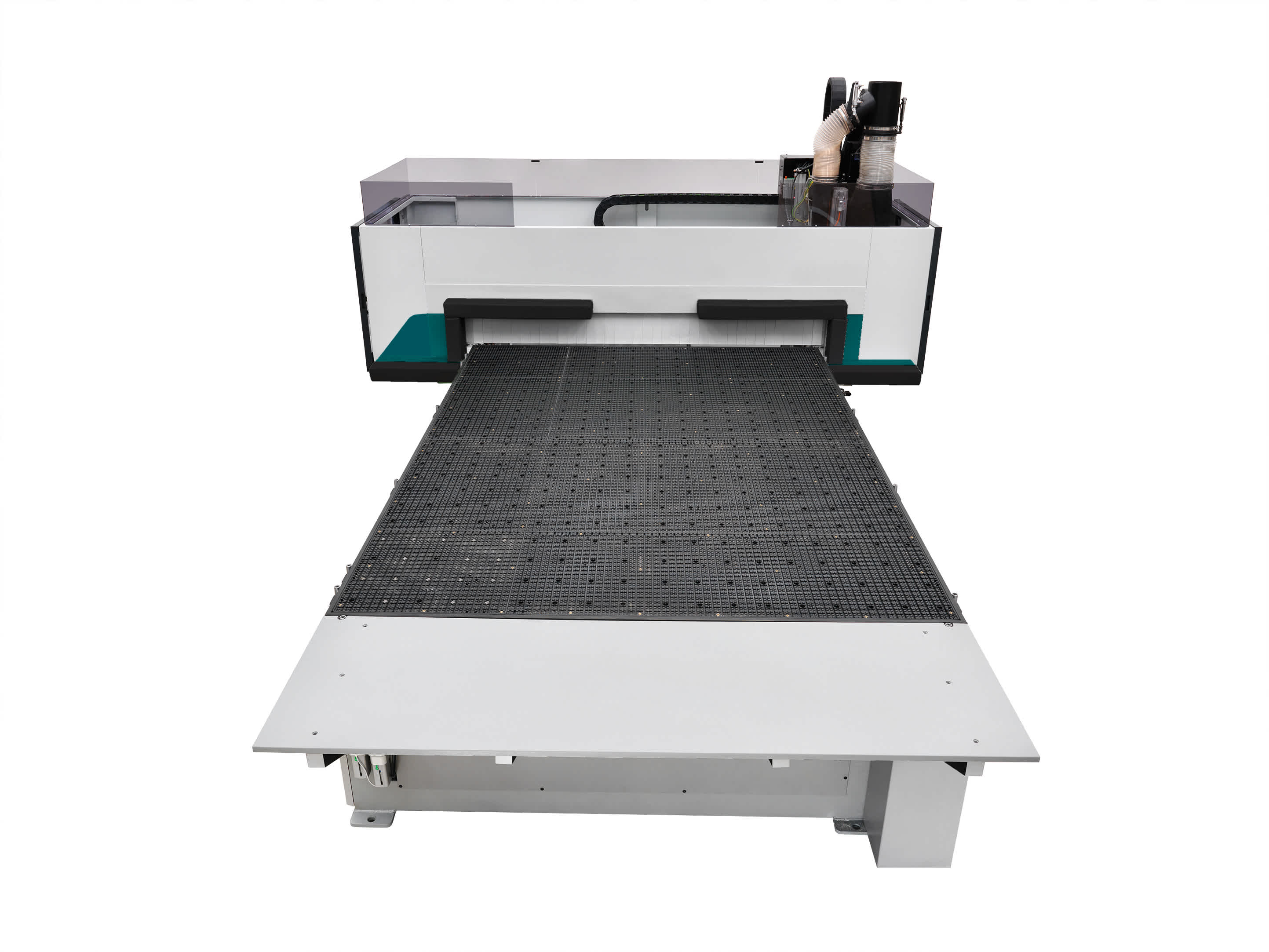

Automatic vacuum system

The worktable is divided into independently controlled vacuum zones, ensuring optimal holding of panels of different sizes while minimizing vacuum loss and preventing workpiece damage.

Technical Specifications

Sectors & Applications

Advertising

Building

Packaging

Customer Care

Kundenspezifische Lösungen, schnelle und effiziente Antworten, Digitalisierung der Erfahrungen für sofortige Zufriedenheit