Reliable. Precise. Built to perform.

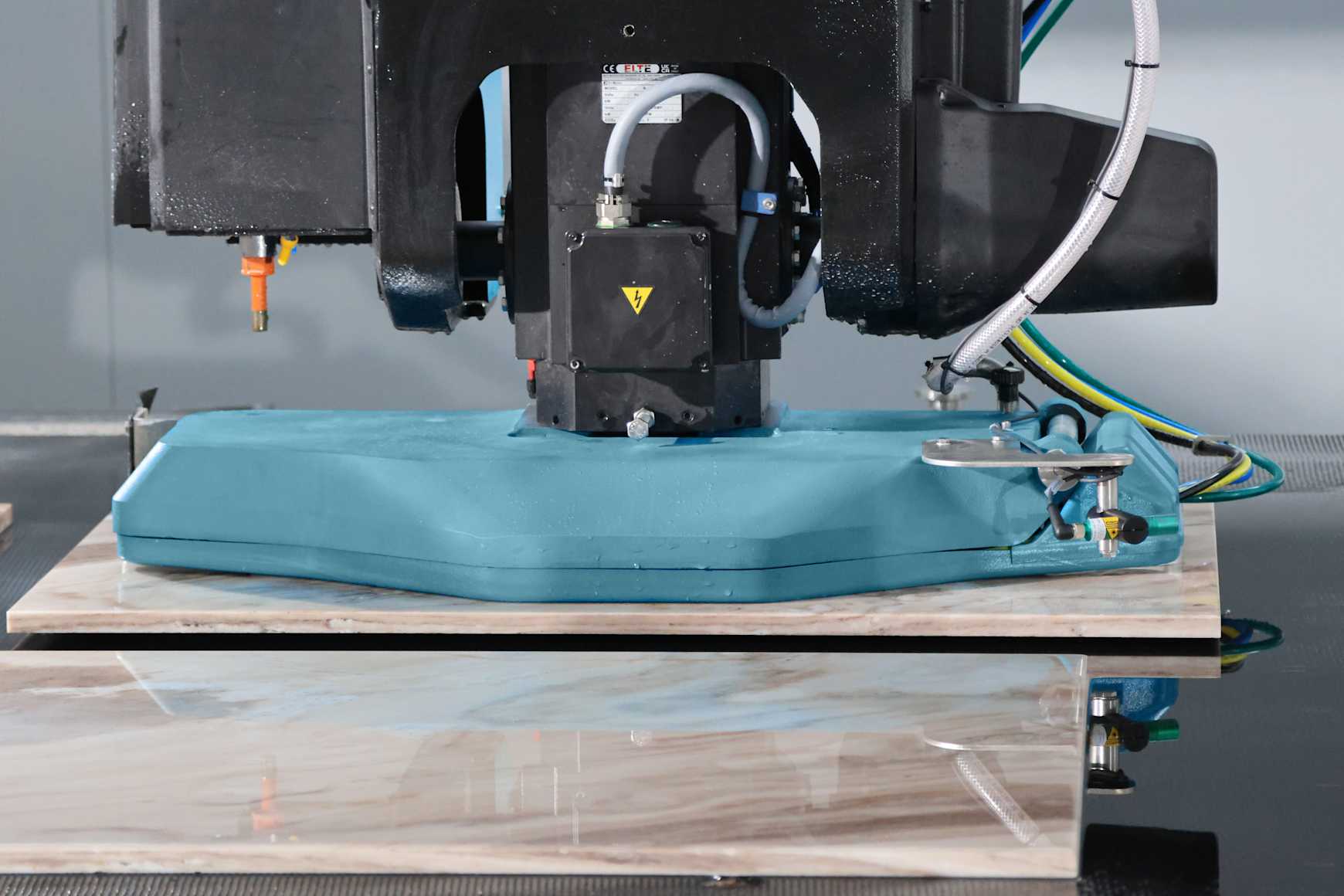

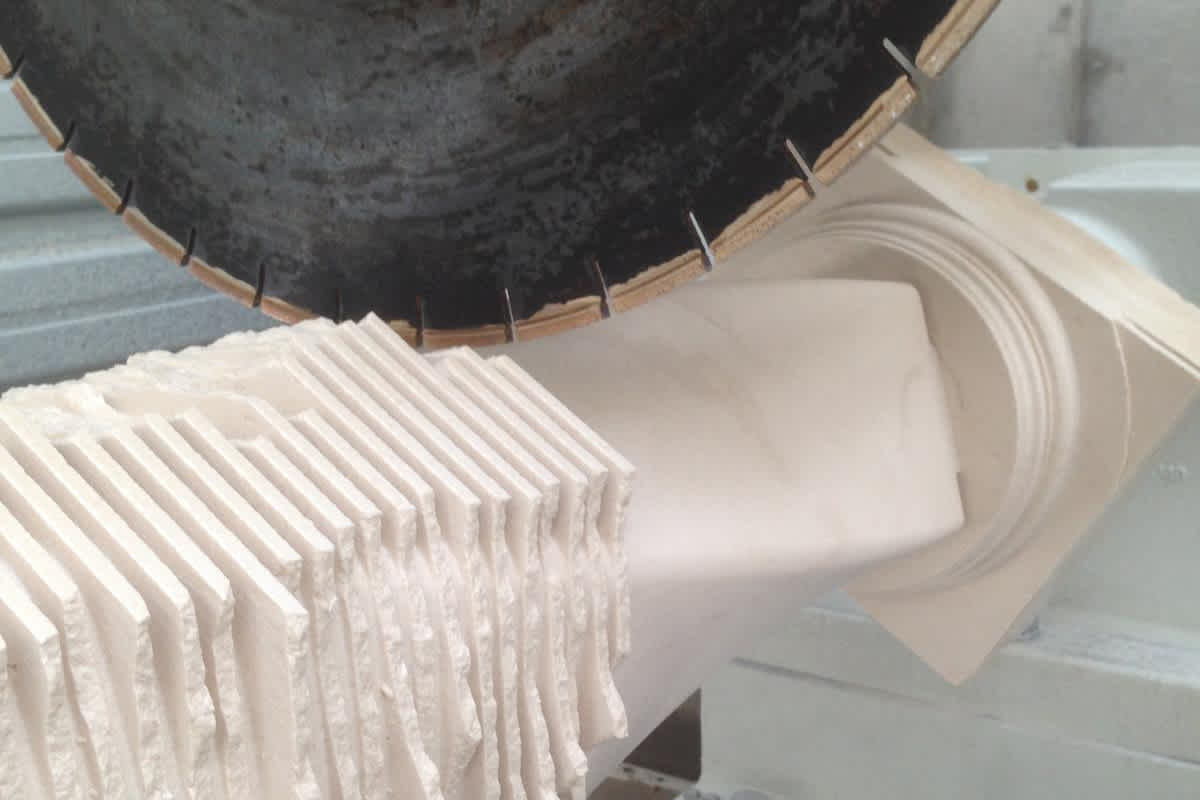

Master Cut Pro C W is a 5-axis CNC bridge saw designed for slabs and small-to-medium thickness stone blocks. Its robust structure and high-precision 5-axis head enable complex and customized cuts with excellent accuracy and efficiency. It is the ideal solution for homeware, architectural and funerary applications, supporting both repetitive workflows and bespoke production.

Control at your fingertips: smart, intuitive and ready to go. The 21″ ergonomic multitouch HMI is integrated into the machine controls, supported by GMM software designed to be simple, innovative and intuitive, enabling quick and efficient start-up of any stone-processing job.

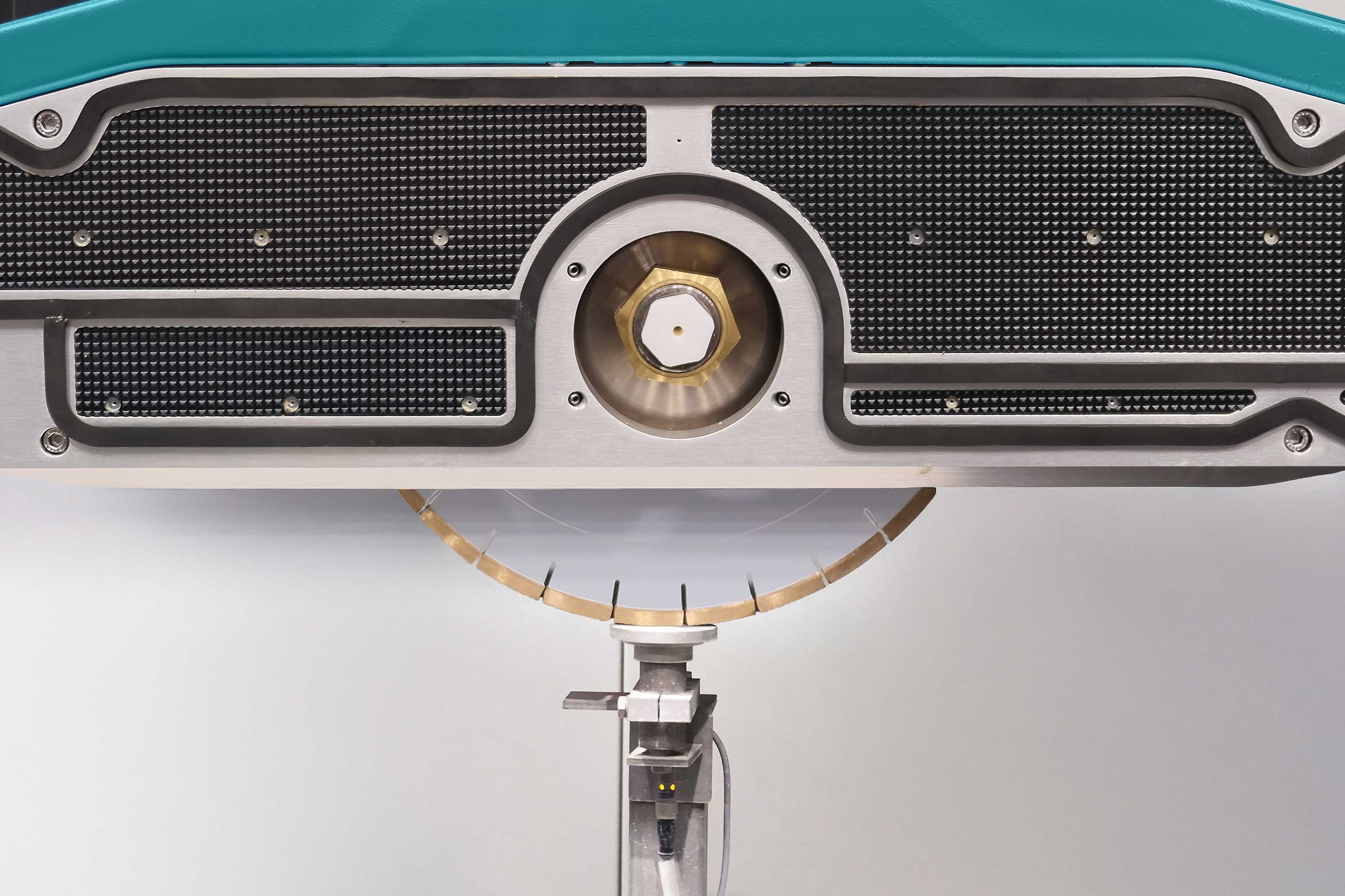

Real-time control for flawless machining. The Tool Diameter Reader precisely measures cutting tools and integrates with the machine software. It monitors wear and enables automatic adjustments, ensuring reliable, consistent, and highly accurate processing every time.

Main Tech data

Sectors & Applications