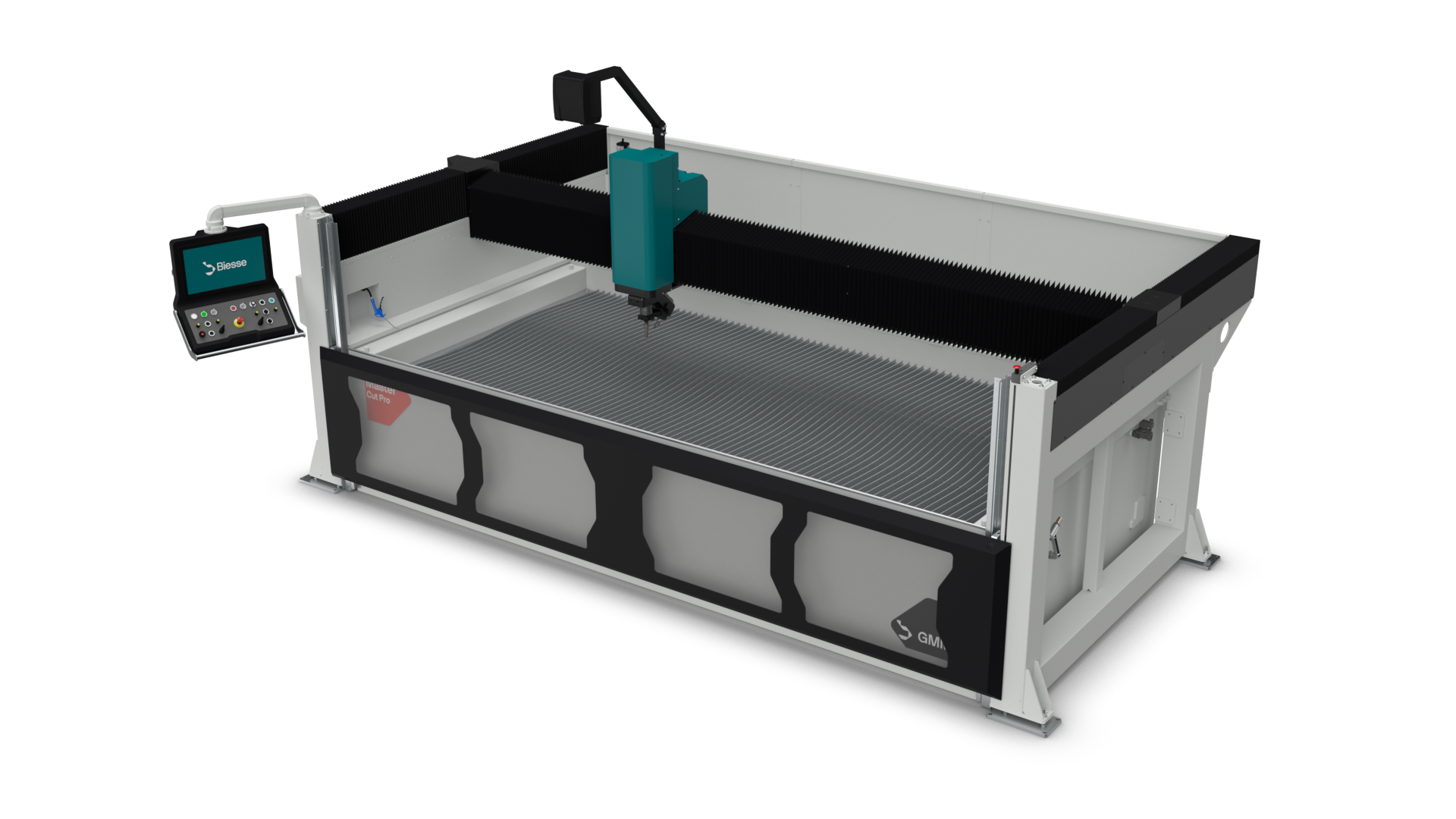

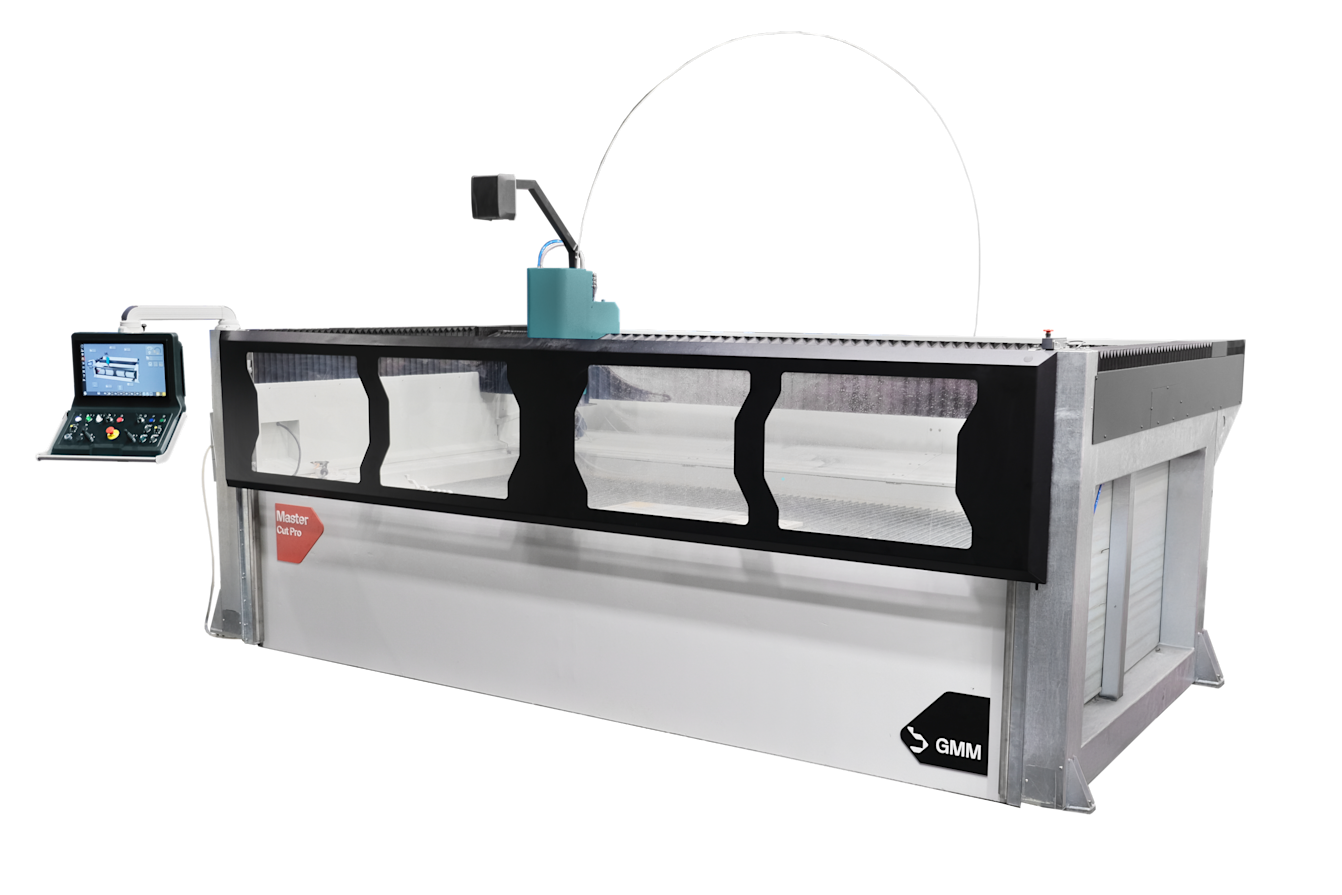

Waterjet machine power for unlimited creativity with simplified workflows.

The Master Cut Pro J C sets a new benchmark in waterjet precision for stone and ceramic materials, offering a clean, safe and fully controlled workflow. With a high-efficiency electric pump and an endless-rotation tilting head, it delivers silent efficiency and total freedom in complex cuts.

Control at your fingertips: smart, intuitive and ready to go. The 21″ ergonomic multitouch HMI is integrated into the machine controls, supported by GMM software designed to be simple, innovative and intuitive, enabling quick and efficient start-up of any stone-processing job.

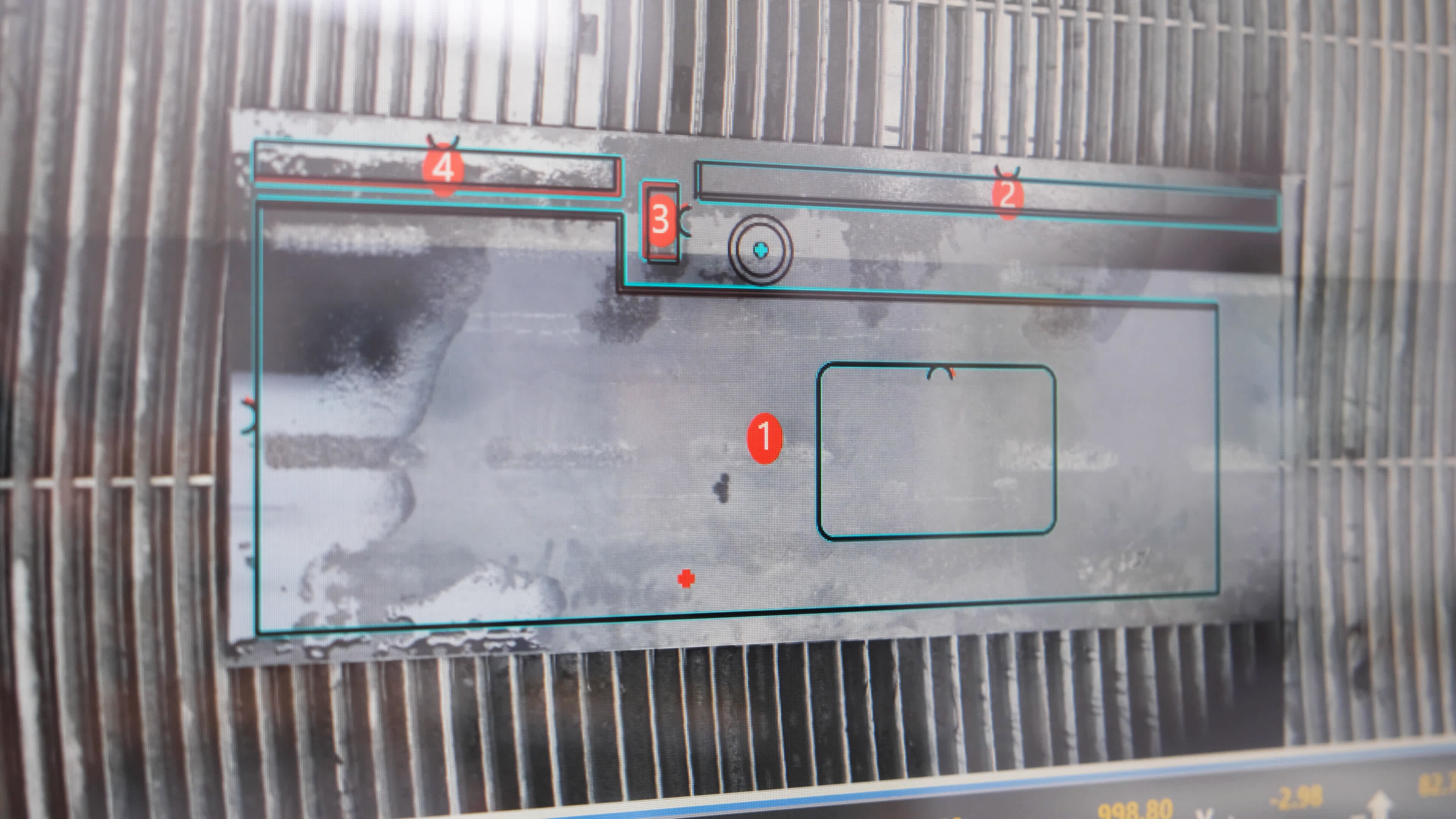

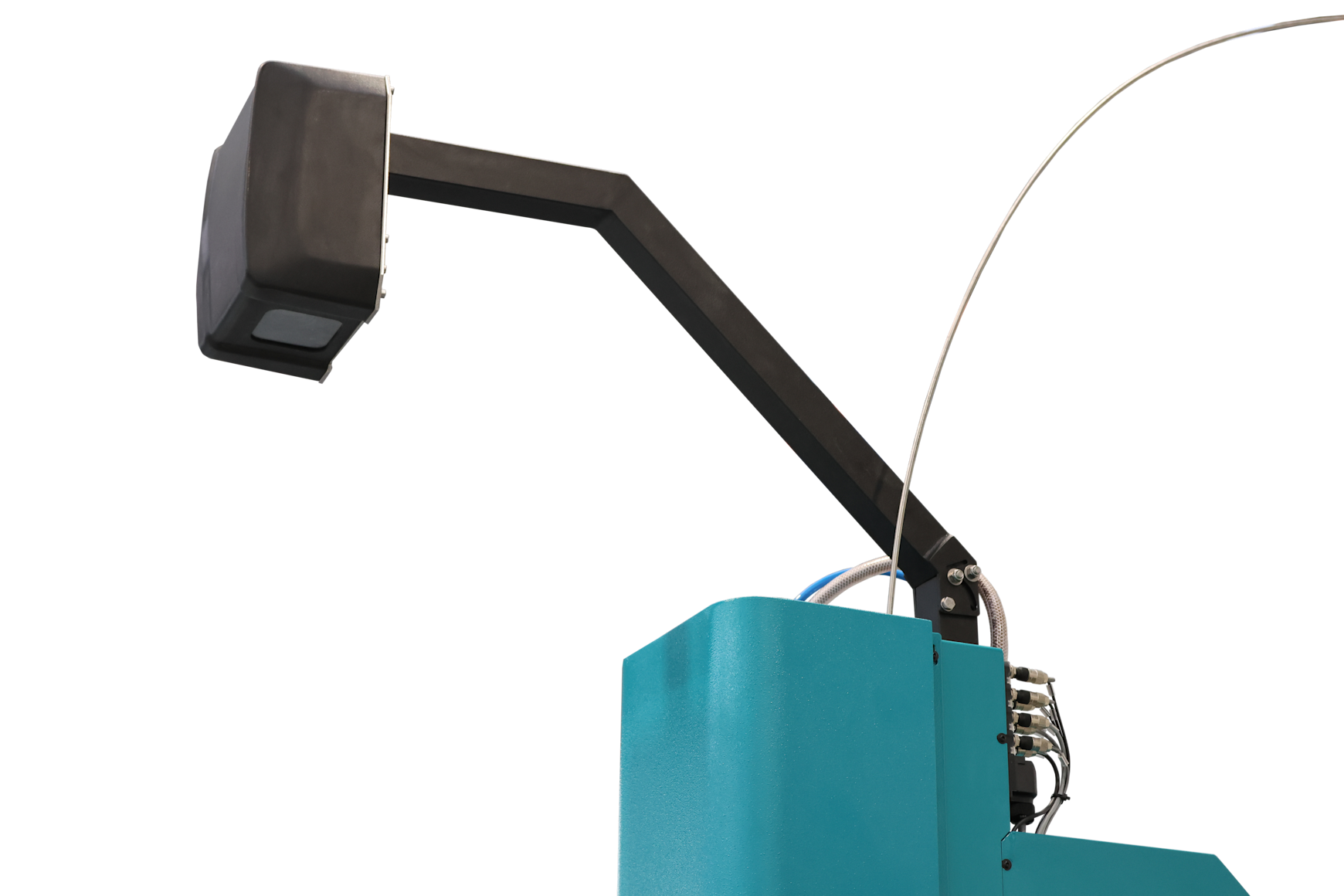

The right point of view. The Camera, integrated on top of the machine head, moves with it to capture the optimal perspective of each slab. This ensures precise edge detection, accurate measurements, and efficient, error-free machining.

Main Technical Data

Sectors & Applications