Flexibility and versatility in every cut.

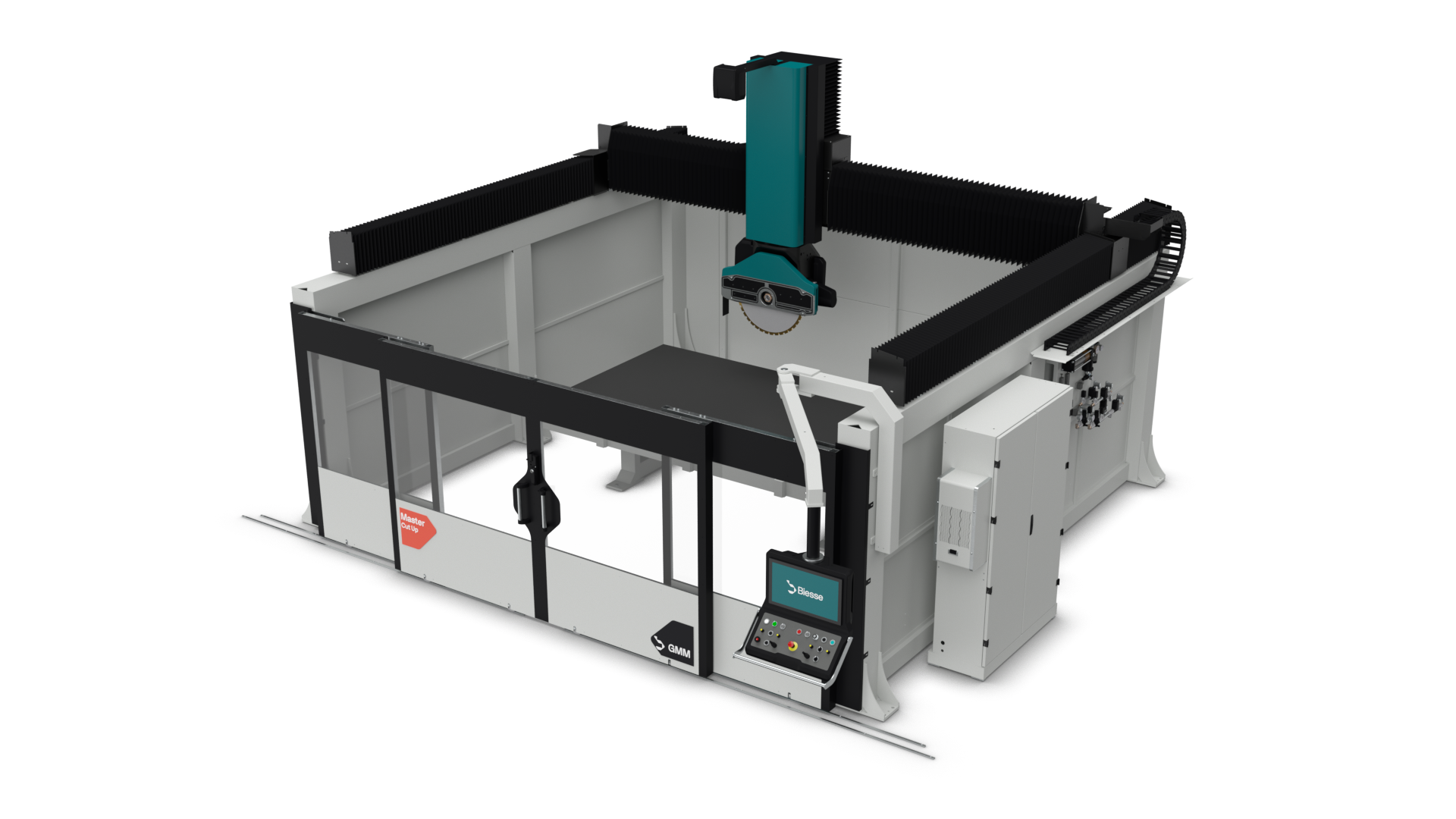

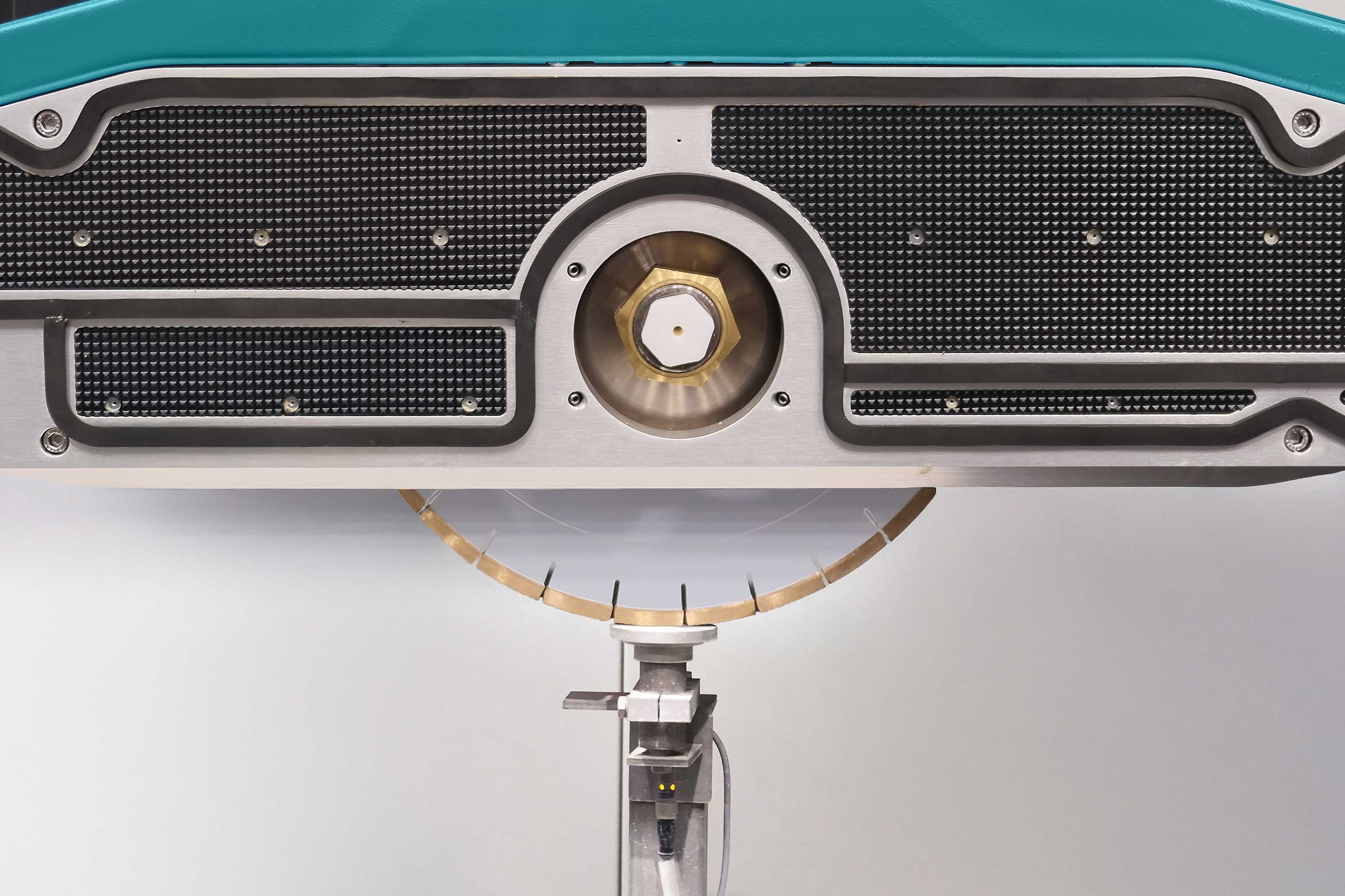

Master Cut UP C W is a mid-size 5-axis CNC sawing machine that combines precision, power and ease of use in a compact footprint. With a 600 mm Z-axis stroke and a Ø 725 mm blade, it processes slabs and medium-thickness stone elements with efficiency and accuracy. Intuitive and reliable, it is ideal for homeware decoration, small architectural projects and funerary applications, supporting both repetitive and custom production.

Control at your fingertips: smart, intuitive and ready to go. The 21″ ergonomic multitouch HMI is integrated into the machine controls, supported by GMM software designed to be simple, innovative and intuitive, enabling quick and efficient start-up of any stone-processing job.

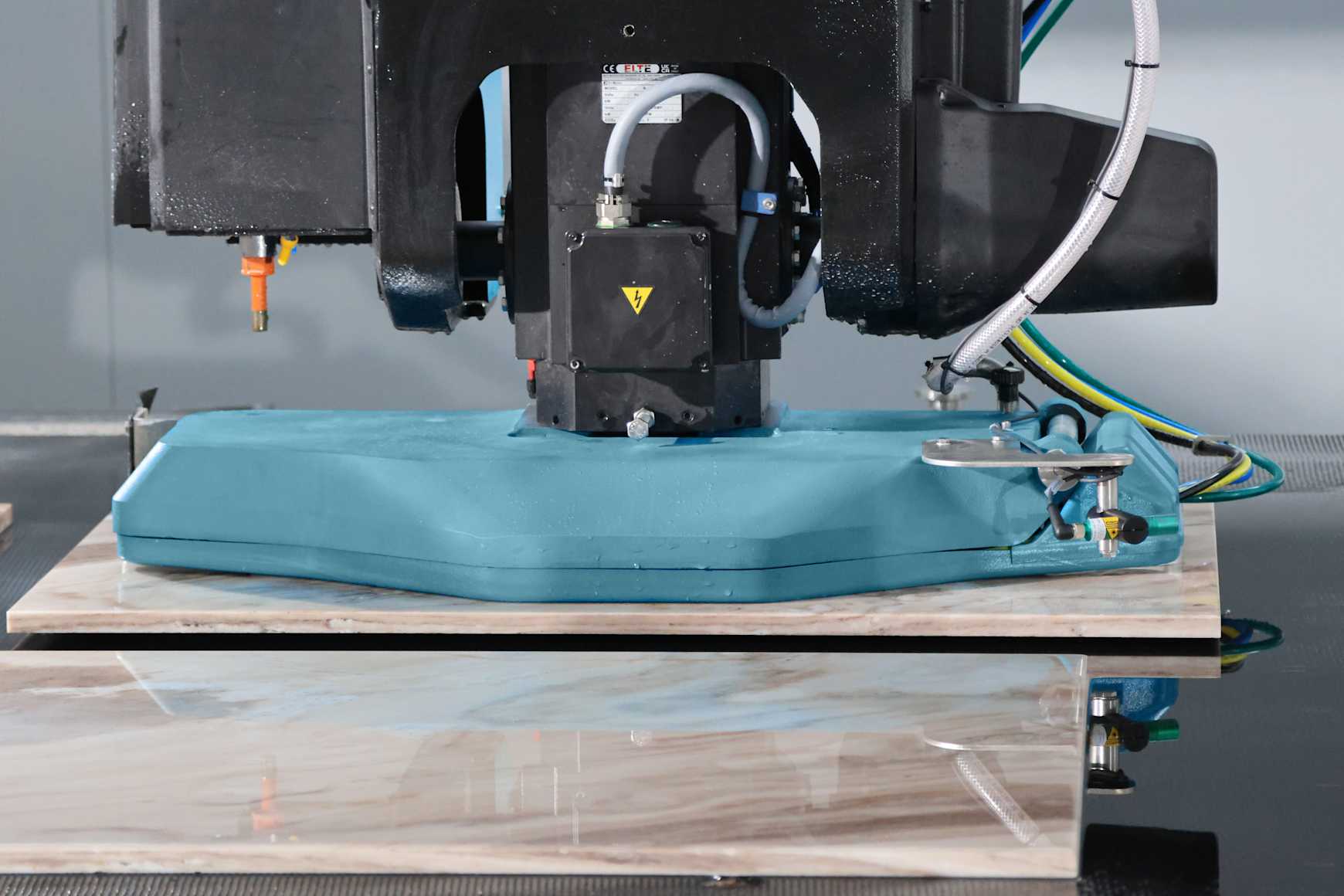

Automatic precision for perfect cuts. The Slab Thickness Reader measures slab thickness and automatically compensates for variations. This ensures consistent cutting accuracy, optimized material use, and precise results, even for complex operations like inclined cuts.

Main Techinical Data

Sectors & Applications