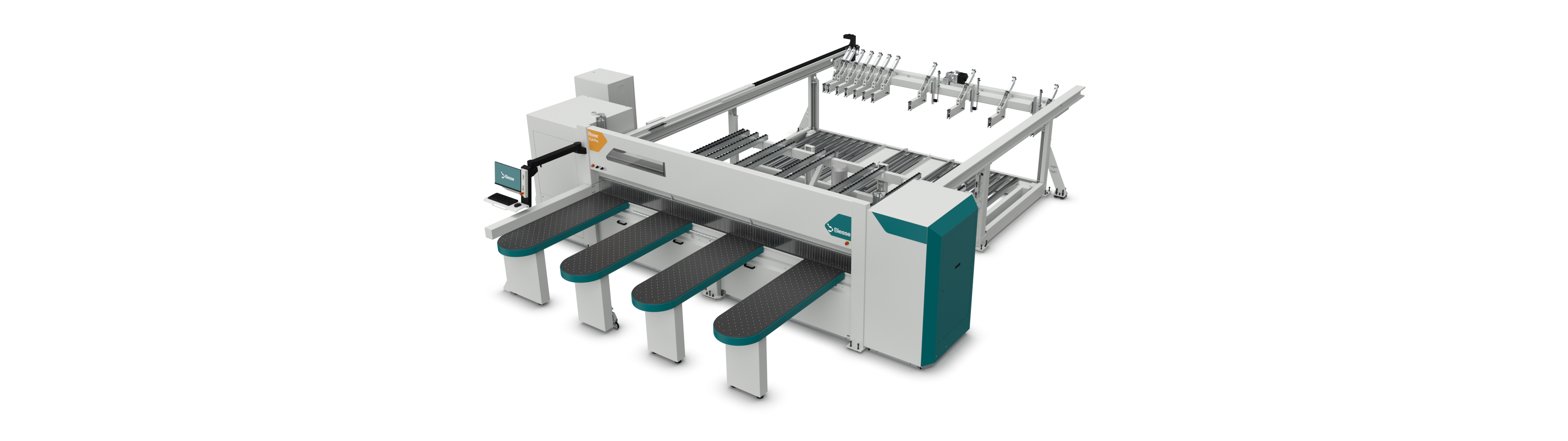

Rover Cut Pro S T

Boost your productivity: rear automatic loading machine designed for high-volume efficiency

Production empowered: rear automatic loading machine suited for productivity-oriented companies. High performance machine with a full-lenght lift table to speed up the cutting process. Suited for companies with a production based on high-batches and volumes.

Services

Personalised solutions, quick and efficient answers, and digitalised experiences for immediate satisfaction

Copyright Biesse | CF e P.IVA IT 00113220412 Reg. Imp. Pesaro Urbino Nr. 1682 | Cap. Soc. € 27.402.593 i.v